Analysis of the high-precision fluid control capability of metal magnetic gear pump

Release Time : 2025-06-30

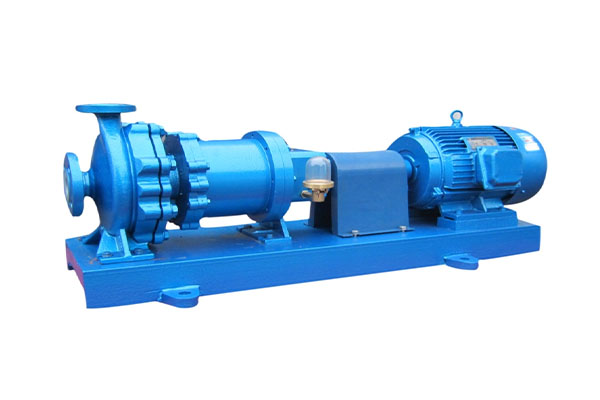

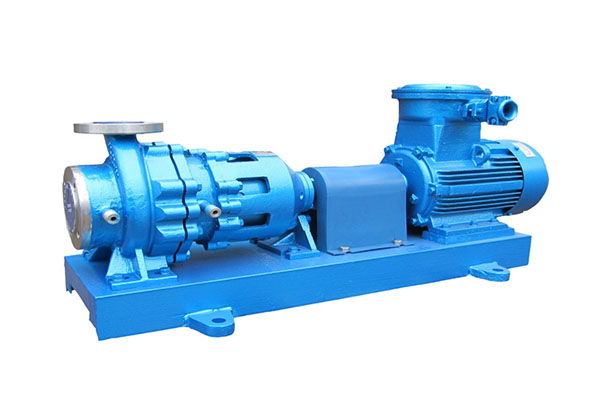

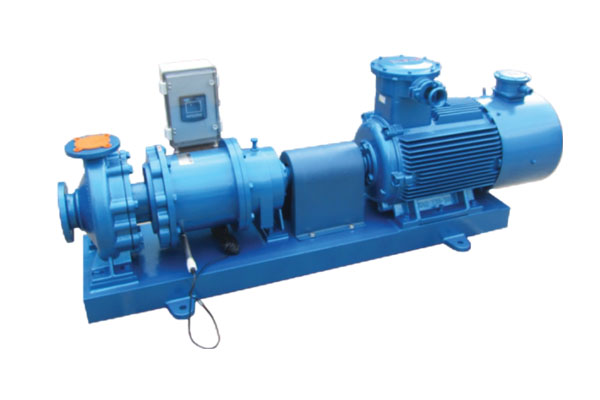

In modern industrial production, the precision requirements for liquid delivery systems are increasing, especially in the fields of chemical, pharmaceutical, food processing and precision manufacturing. The flow rate, pressure and delivery stability of the fluid directly affect the product quality and process efficiency. Metal magnetic gear pump stands out in this demand background. With its excellent high-precision fluid control capability, it has become the preferred equipment for many high-end applications.

Precision structural design improves flow control accuracy

The metal magnetic gear pump is manufactured using an integrated casting process, and the internal gear system is processed by high-precision CNC to ensure the close cooperation and movement coordination between the components. This refined design not only improves the overall rigidity of the pump body, but also effectively reduces the vibration and offset during operation, so that the volume of liquid driven by each gear rotation remains highly consistent. By accurately calculating the relationship between the gear modulus, tooth gap and speed, the pump can achieve micron-level flow regulation within the set range, meeting the strict requirements for trace or continuous and constant liquid supply.

Leak-free sealing technology ensures a stable delivery environment

Traditional mechanical seal pumps are prone to leakage due to wear during long-term operation, which in turn affects the accuracy of fluid control. The metal magnetic gear pump adopts a fully enclosed magnetic drive structure, cancels the traditional shaft seal design, and fundamentally eliminates the risk of leakage. This sealing method not only improves safety, but more importantly, provides a constant, non-interference-free delivery channel for the fluid, thereby ensuring the long-term stability of the output pressure and flow rate, which is particularly suitable for high-precision operation scenarios that require continuous operation and do not allow interruptions.

Multi-parameter collaborative regulation optimizes control performance

With the continuous improvement of the level of industrial automation, the metal magnetic gear pump is gradually developing in the direction of intelligence. Modern products are usually equipped with intelligent components such as adjustable frequency motors, pressure sensors, and flow monitoring modules, which can collect operating data in real time and work in conjunction with the control system for closed-loop regulation. For example, in the process of conveying certain high-viscosity materials, the system can automatically adjust the pump speed according to the feedback pressure changes to maintain a constant output flow rate and avoid control errors caused by fluctuations in material properties. This multi-parameter collaborative regulation mechanism greatly enhances the adaptability and response speed of the pump, and further improves the overall control accuracy.

Materials and surface treatment technology extend service life and reduce error accumulation

Metal magnetic gear pump widely uses high-performance metal materials such as stainless steel, Hastelloy, titanium alloy, etc. These materials not only have excellent corrosion resistance, but also maintain good dimensional stability under high temperature and high pressure environment. In addition, some key components have undergone special hardening and polishing treatments to reduce the friction coefficient, reduce wear and thermal deformation problems during operation. After long-term use, it can still maintain high geometric accuracy, avoid flow deviation caused by aging of parts, and thus ensure the high-precision performance of the equipment throughout its life cycle.

Widely used in industries with strict requirements on control accuracy

The high-precision fluid control capability of metal magnetic gear pump has been widely verified in many fields. In the pharmaceutical industry, it is used to accurately measure and deliver high-value liquid medicines to ensure the consistency of the ingredients of each batch of products; in semiconductor manufacturing, it is used to deliver ultra-pure chemicals to prevent wafer contamination due to small flow fluctuations; in food processing, it is used for quantitative filling and batching to ensure the consistency of product quality. These application scenarios have extremely high requirements for fluid control, and metal magnetic gear pump has successfully met these challenges with its excellent stability and precision.

The reason why the metal magnetic gear pump can perform well in high-precision fluid control is inseparable from its precise structural design, advanced sealing technology, intelligent control methods and high-quality material selection. It not only achieves precise control of flow and pressure, but also maintains stable performance in long-term operation, providing strong support for efficient and high-quality production in modern industry.

Precision structural design improves flow control accuracy

The metal magnetic gear pump is manufactured using an integrated casting process, and the internal gear system is processed by high-precision CNC to ensure the close cooperation and movement coordination between the components. This refined design not only improves the overall rigidity of the pump body, but also effectively reduces the vibration and offset during operation, so that the volume of liquid driven by each gear rotation remains highly consistent. By accurately calculating the relationship between the gear modulus, tooth gap and speed, the pump can achieve micron-level flow regulation within the set range, meeting the strict requirements for trace or continuous and constant liquid supply.

Leak-free sealing technology ensures a stable delivery environment

Traditional mechanical seal pumps are prone to leakage due to wear during long-term operation, which in turn affects the accuracy of fluid control. The metal magnetic gear pump adopts a fully enclosed magnetic drive structure, cancels the traditional shaft seal design, and fundamentally eliminates the risk of leakage. This sealing method not only improves safety, but more importantly, provides a constant, non-interference-free delivery channel for the fluid, thereby ensuring the long-term stability of the output pressure and flow rate, which is particularly suitable for high-precision operation scenarios that require continuous operation and do not allow interruptions.

Multi-parameter collaborative regulation optimizes control performance

With the continuous improvement of the level of industrial automation, the metal magnetic gear pump is gradually developing in the direction of intelligence. Modern products are usually equipped with intelligent components such as adjustable frequency motors, pressure sensors, and flow monitoring modules, which can collect operating data in real time and work in conjunction with the control system for closed-loop regulation. For example, in the process of conveying certain high-viscosity materials, the system can automatically adjust the pump speed according to the feedback pressure changes to maintain a constant output flow rate and avoid control errors caused by fluctuations in material properties. This multi-parameter collaborative regulation mechanism greatly enhances the adaptability and response speed of the pump, and further improves the overall control accuracy.

Materials and surface treatment technology extend service life and reduce error accumulation

Metal magnetic gear pump widely uses high-performance metal materials such as stainless steel, Hastelloy, titanium alloy, etc. These materials not only have excellent corrosion resistance, but also maintain good dimensional stability under high temperature and high pressure environment. In addition, some key components have undergone special hardening and polishing treatments to reduce the friction coefficient, reduce wear and thermal deformation problems during operation. After long-term use, it can still maintain high geometric accuracy, avoid flow deviation caused by aging of parts, and thus ensure the high-precision performance of the equipment throughout its life cycle.

Widely used in industries with strict requirements on control accuracy

The high-precision fluid control capability of metal magnetic gear pump has been widely verified in many fields. In the pharmaceutical industry, it is used to accurately measure and deliver high-value liquid medicines to ensure the consistency of the ingredients of each batch of products; in semiconductor manufacturing, it is used to deliver ultra-pure chemicals to prevent wafer contamination due to small flow fluctuations; in food processing, it is used for quantitative filling and batching to ensure the consistency of product quality. These application scenarios have extremely high requirements for fluid control, and metal magnetic gear pump has successfully met these challenges with its excellent stability and precision.

The reason why the metal magnetic gear pump can perform well in high-precision fluid control is inseparable from its precise structural design, advanced sealing technology, intelligent control methods and high-quality material selection. It not only achieves precise control of flow and pressure, but also maintains stable performance in long-term operation, providing strong support for efficient and high-quality production in modern industry.