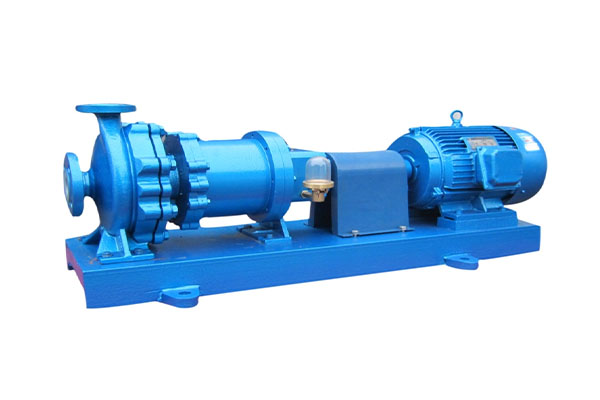

Application of IMC plastic magnetic centrifugal pump in harsh environments

Release Time : 2025-04-09

In many industries such as chemical, pharmaceutical, electronic, and food processing, the demand for pumps is not limited to basic liquid delivery functions, but also requires them to be able to operate stably under various extreme conditions. IMC plastic magnetic centrifugal pump has shown irreplaceable value in these harsh environments due to its unique design and excellent performance.

1. Corrosion resistance: a weapon to deal with chemical erosion

The chemical industry is one of the fields where pumps are used most, and the fluids handled are often highly corrosive. Traditional metal pumps are easily corroded in this environment, causing equipment damage or leakage, which in turn affects production safety and efficiency. In contrast, IMC plastic magnetic centrifugal pumps are made of high-performance plastic materials such as polypropylene (PP) and polyvinylidene fluoride (PVDF), which have excellent chemical corrosion resistance and can resist the erosion of most acid and alkali solutions and organic solvents. Therefore, they are particularly suitable for working conditions containing highly corrosive media, such as the transportation of chemicals such as sulfuric acid, sodium hydroxide, and sodium chloride.

2. Leak-free design: the key to ensuring safe production

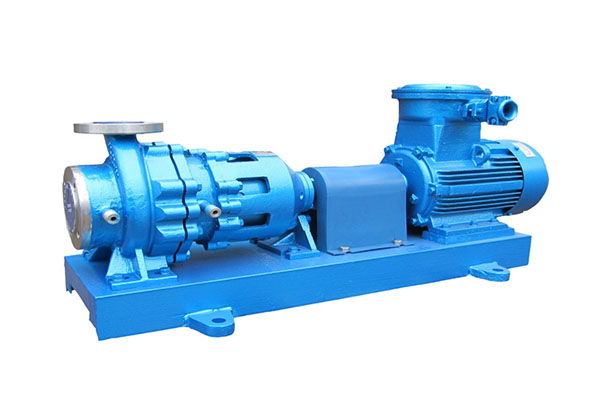

In many industrial processes, even a trace amount of leakage can have serious consequences, especially when dealing with toxic and hazardous substances. IMC plastic magnetic centrifugal pump uses magnetic drive technology to completely eliminate the risk of leakage caused by shaft seals. Traditional mechanical seal pumps rely on physical contact to prevent fluid leakage, but this structure is prone to wear and requires regular maintenance. The magnetic drive transfers power from the motor to the impeller through the action of the magnetic field. The entire system is closed, ensuring absolute sealing and providing strong protection for the safety of operators.

3. High efficiency and energy saving: an ideal choice for achieving green production

With the increasing global awareness of environmental protection, companies are paying more and more attention to energy conservation and emission reduction. Due to its optimized design, IMC plastic magnetic centrifugal pump reduces energy consumption while improving work efficiency. The efficient hydraulic design reduces energy loss, making the pump more energy-efficient than traditional pumps under the same working conditions. In addition, due to its light material and easy installation, the total cost of the system is further reduced. For modern enterprises pursuing sustainable development, choosing IMC plastic magnetic centrifugal pump not only helps to reduce operating costs, but also is a concrete manifestation of fulfilling social responsibility.

4. Adapt to harsh working conditions: beyond the conventional application range

In addition to the above characteristics, IMC plastic magnetic centrifugal pump also has good wear resistance and impact resistance, which enables it to work normally in complex environments with large temperature changes and high particle content. For example, in the fields of ore flotation and sewage treatment, the pump not only faces the wear of high-concentration suspended particles, but also has to withstand frequent temperature fluctuations. With its rugged and durable structure and excellent material properties, IMC plastic magnetic centrifugal pump can easily cope with these challenges and ensure the continuity and stability of the production line.

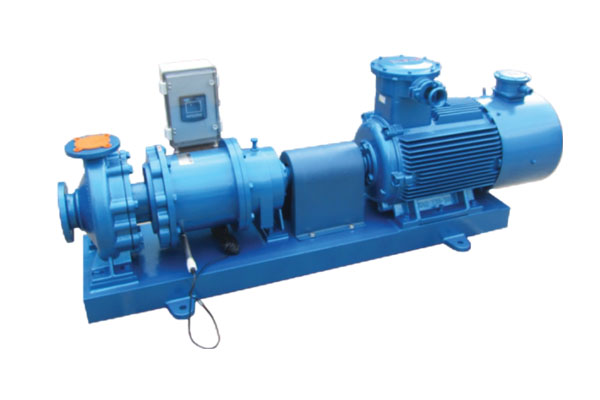

5. Intelligent monitoring and maintenance convenience: a new way to improve management efficiency

Modern IMC plastic magnetic centrifugal pumps are usually equipped with intelligent monitoring systems that can track various operating parameters of the pump in real time, such as flow, pressure, temperature, etc. Once an abnormal situation is detected, the system will immediately issue an alarm to remind the operator to take timely measures to prevent the fault from expanding. At the same time, this intelligent design also greatly simplifies daily maintenance work, reduces downtime, and improves the overall management level.

In summary, IMC plastic magnetic centrifugal pump plays an important role in harsh environments of chemical, pharmaceutical and other industries with its excellent corrosion resistance, leak-free design, high efficiency and energy saving, and ability to adapt to harsh working conditions. It not only helps enterprises solve many problems in the production process, but also contributes to promoting the green development of various industries.

1. Corrosion resistance: a weapon to deal with chemical erosion

The chemical industry is one of the fields where pumps are used most, and the fluids handled are often highly corrosive. Traditional metal pumps are easily corroded in this environment, causing equipment damage or leakage, which in turn affects production safety and efficiency. In contrast, IMC plastic magnetic centrifugal pumps are made of high-performance plastic materials such as polypropylene (PP) and polyvinylidene fluoride (PVDF), which have excellent chemical corrosion resistance and can resist the erosion of most acid and alkali solutions and organic solvents. Therefore, they are particularly suitable for working conditions containing highly corrosive media, such as the transportation of chemicals such as sulfuric acid, sodium hydroxide, and sodium chloride.

2. Leak-free design: the key to ensuring safe production

In many industrial processes, even a trace amount of leakage can have serious consequences, especially when dealing with toxic and hazardous substances. IMC plastic magnetic centrifugal pump uses magnetic drive technology to completely eliminate the risk of leakage caused by shaft seals. Traditional mechanical seal pumps rely on physical contact to prevent fluid leakage, but this structure is prone to wear and requires regular maintenance. The magnetic drive transfers power from the motor to the impeller through the action of the magnetic field. The entire system is closed, ensuring absolute sealing and providing strong protection for the safety of operators.

3. High efficiency and energy saving: an ideal choice for achieving green production

With the increasing global awareness of environmental protection, companies are paying more and more attention to energy conservation and emission reduction. Due to its optimized design, IMC plastic magnetic centrifugal pump reduces energy consumption while improving work efficiency. The efficient hydraulic design reduces energy loss, making the pump more energy-efficient than traditional pumps under the same working conditions. In addition, due to its light material and easy installation, the total cost of the system is further reduced. For modern enterprises pursuing sustainable development, choosing IMC plastic magnetic centrifugal pump not only helps to reduce operating costs, but also is a concrete manifestation of fulfilling social responsibility.

4. Adapt to harsh working conditions: beyond the conventional application range

In addition to the above characteristics, IMC plastic magnetic centrifugal pump also has good wear resistance and impact resistance, which enables it to work normally in complex environments with large temperature changes and high particle content. For example, in the fields of ore flotation and sewage treatment, the pump not only faces the wear of high-concentration suspended particles, but also has to withstand frequent temperature fluctuations. With its rugged and durable structure and excellent material properties, IMC plastic magnetic centrifugal pump can easily cope with these challenges and ensure the continuity and stability of the production line.

5. Intelligent monitoring and maintenance convenience: a new way to improve management efficiency

Modern IMC plastic magnetic centrifugal pumps are usually equipped with intelligent monitoring systems that can track various operating parameters of the pump in real time, such as flow, pressure, temperature, etc. Once an abnormal situation is detected, the system will immediately issue an alarm to remind the operator to take timely measures to prevent the fault from expanding. At the same time, this intelligent design also greatly simplifies daily maintenance work, reduces downtime, and improves the overall management level.

In summary, IMC plastic magnetic centrifugal pump plays an important role in harsh environments of chemical, pharmaceutical and other industries with its excellent corrosion resistance, leak-free design, high efficiency and energy saving, and ability to adapt to harsh working conditions. It not only helps enterprises solve many problems in the production process, but also contributes to promoting the green development of various industries.