How does the imc metal magnetic split flow pump effectively avoid cavitation and ensure the continuous and efficient operation of the pump?

Release Time : 2025-04-22

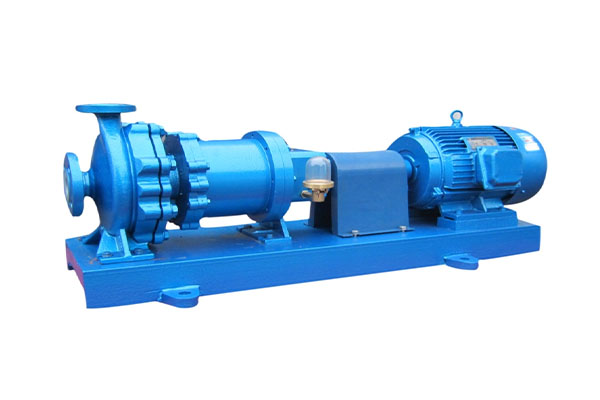

The imc metal magnetic split flow pump fully considers the avoidance of cavitation during the design and manufacturing process to ensure that it can operate continuously and efficiently. Cavitation is a phenomenon in which the internal components of the pump are damaged due to the rapid collapse of vapor bubbles in the liquid in the high-pressure area. It not only reduces the performance of the pump, but also may cause serious mechanical damage. Therefore, how to effectively prevent cavitation is crucial to ensure the long-term stable operation of the pump.

First of all, the imc metal magnetic split flow pump adopts an optimized flow channel design, which helps to reduce the velocity change of the fluid when it enters the pump body, thereby reducing the possibility of vapor bubble formation. Through precise calculation and simulation analysis, the designers determined the optimal inlet angle and flow channel shape, so that the fluid can transition smoothly, reducing the risk of turbulence and pressure drop. This carefully designed flow channel structure not only improves the overall efficiency of the pump, but also effectively suppresses the occurrence of cavitation.

In addition, the imc metal magnetic split flow pump uses high-quality materials to enhance its anti-cavitation ability. These materials have excellent corrosion resistance and wear resistance, and can maintain good physical properties under extreme conditions. For example, some key components may use special alloys or coating technologies that are not only resistant to chemical attack, but also able to withstand the local high-pressure shock caused by the collapse of bubbles. In this way, even in the case of possible minor cavitation, the main working parts of the pump can be effectively protected, extending the service life and maintaining stable performance output.

Another important anti-cavitation strategy is to control the operating conditions of the pump. The imc metal magnetic split flow pump is equipped with an advanced control system that allows operators to adjust the operating parameters of the pump according to the actual working conditions. For example, when handling volatile media or working in a high-temperature and low-pressure environment, the risk of cavitation can be reduced by appropriately reducing the pump speed or increasing the pressure on the suction side. At the same time, the real-time monitoring system can detect any abnormalities in time and take corresponding measures to make adjustments to ensure that the pump is always in optimal working condition.

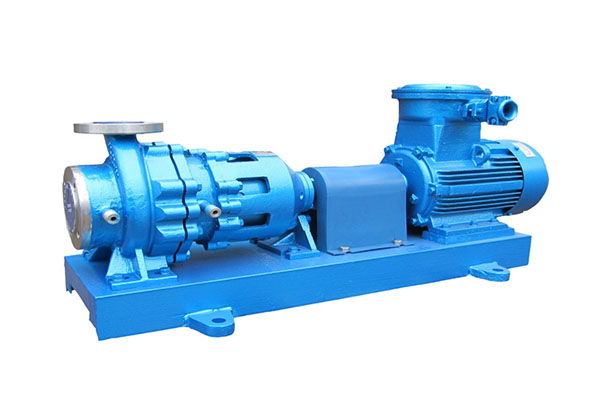

Furthermore, the imc metal magnetic split flow pump has also made special considerations in the installation layout to further prevent cavitation problems. Reasonable pipe layout and sufficient net positive suction head (NPSH) are one of the key factors in preventing cavitation. To achieve this goal, it is usually necessary to ensure that the water inlet pipe is as short and straight as possible, and avoid the presence of too many elbows and valves, as these will increase fluid resistance and cause pressure drop. In addition, attention should be paid to the location of the pump so that it is deep enough below the liquid surface to provide sufficient NPSH, thereby fundamentally eliminating the possibility of cavitation.

Finally, regular maintenance and inspection are also important links to ensure that the imc metal magnetic split flow pump does not cavitate. Although modern design and technology have greatly reduced the risk of cavitation, factors such as wear and sediment accumulation may still affect the performance of the pump over time. Therefore, establishing a comprehensive preventive maintenance plan, including steps such as cleaning, lubrication, and replacement of damaged parts when necessary, will help to detect potential problems in a timely manner and solve them, ensuring the long-term and reliable operation of the pump.

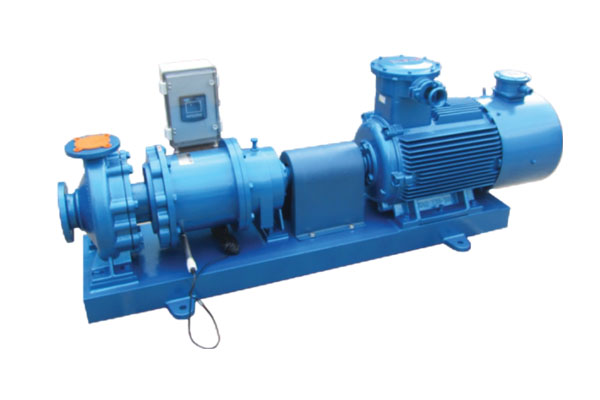

In summary, the imc metal magnetic split flow pump has comprehensively improved its ability to resist cavitation through a series of carefully designed measures, from hardware selection to software control to daily maintenance. This not only ensures the continuous and efficient operation of the pump, but also brings higher economic benefits and social value to users. In this era of pursuing high efficiency and sustainable development, the imc metal magnetic split flow pump has undoubtedly become the ideal choice for many industry users with its excellent anti-cavitation performance.

First of all, the imc metal magnetic split flow pump adopts an optimized flow channel design, which helps to reduce the velocity change of the fluid when it enters the pump body, thereby reducing the possibility of vapor bubble formation. Through precise calculation and simulation analysis, the designers determined the optimal inlet angle and flow channel shape, so that the fluid can transition smoothly, reducing the risk of turbulence and pressure drop. This carefully designed flow channel structure not only improves the overall efficiency of the pump, but also effectively suppresses the occurrence of cavitation.

In addition, the imc metal magnetic split flow pump uses high-quality materials to enhance its anti-cavitation ability. These materials have excellent corrosion resistance and wear resistance, and can maintain good physical properties under extreme conditions. For example, some key components may use special alloys or coating technologies that are not only resistant to chemical attack, but also able to withstand the local high-pressure shock caused by the collapse of bubbles. In this way, even in the case of possible minor cavitation, the main working parts of the pump can be effectively protected, extending the service life and maintaining stable performance output.

Another important anti-cavitation strategy is to control the operating conditions of the pump. The imc metal magnetic split flow pump is equipped with an advanced control system that allows operators to adjust the operating parameters of the pump according to the actual working conditions. For example, when handling volatile media or working in a high-temperature and low-pressure environment, the risk of cavitation can be reduced by appropriately reducing the pump speed or increasing the pressure on the suction side. At the same time, the real-time monitoring system can detect any abnormalities in time and take corresponding measures to make adjustments to ensure that the pump is always in optimal working condition.

Furthermore, the imc metal magnetic split flow pump has also made special considerations in the installation layout to further prevent cavitation problems. Reasonable pipe layout and sufficient net positive suction head (NPSH) are one of the key factors in preventing cavitation. To achieve this goal, it is usually necessary to ensure that the water inlet pipe is as short and straight as possible, and avoid the presence of too many elbows and valves, as these will increase fluid resistance and cause pressure drop. In addition, attention should be paid to the location of the pump so that it is deep enough below the liquid surface to provide sufficient NPSH, thereby fundamentally eliminating the possibility of cavitation.

Finally, regular maintenance and inspection are also important links to ensure that the imc metal magnetic split flow pump does not cavitate. Although modern design and technology have greatly reduced the risk of cavitation, factors such as wear and sediment accumulation may still affect the performance of the pump over time. Therefore, establishing a comprehensive preventive maintenance plan, including steps such as cleaning, lubrication, and replacement of damaged parts when necessary, will help to detect potential problems in a timely manner and solve them, ensuring the long-term and reliable operation of the pump.

In summary, the imc metal magnetic split flow pump has comprehensively improved its ability to resist cavitation through a series of carefully designed measures, from hardware selection to software control to daily maintenance. This not only ensures the continuous and efficient operation of the pump, but also brings higher economic benefits and social value to users. In this era of pursuing high efficiency and sustainable development, the imc metal magnetic split flow pump has undoubtedly become the ideal choice for many industry users with its excellent anti-cavitation performance.