How to design the magnetic transmission system of metal magnetic vortex pump to achieve efficient and leak-free operation?

Release Time : 2025-05-07

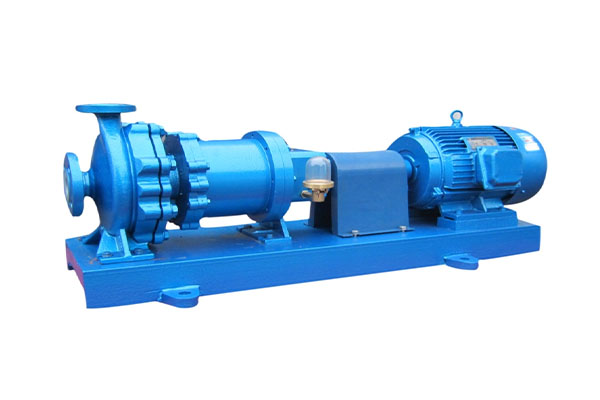

The metal magnetic vortex pump has a unique magnetic transmission system, which shows significant advantages in achieving efficient and leak-free operation. It is widely used in fields with strict requirements for fluid transportation. Its magnetic transmission system is the core component, which undertakes the key task of efficiently transmitting power and ensuring no leakage.

The magnetic transmission system of the metal magnetic vortex pump is based on the principle of magnetic field interaction of permanent magnets. It is usually composed of an inner magnetic rotor and an outer magnetic rotor. The inner magnetic rotor is connected to the impeller of the pump, and the outer magnetic rotor is connected to the drive motor. When the outer magnetic rotor rotates under the drive of the motor, the magnetic field generated by it drives the inner magnetic rotor to rotate synchronously, thereby driving the impeller to rotate and realize the transportation of the fluid. This non-contact transmission method avoids the leakage risk caused by traditional mechanical seals.

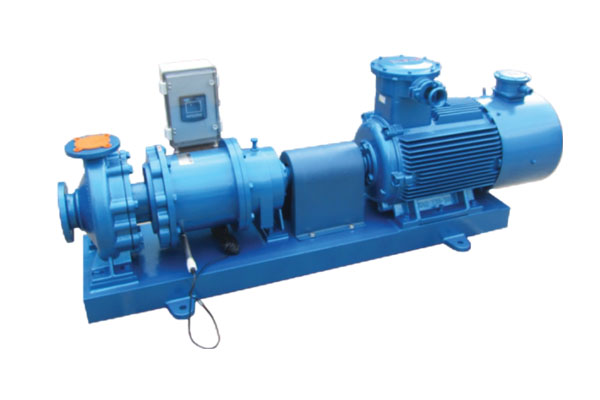

In order to achieve efficient transmission, magnetic circuit design is crucial. First, permanent magnetic materials with high magnetic energy product, such as neodymium iron boron permanent magnets, are selected to enhance the magnetic field strength. Secondly, through precise magnetic circuit calculation and optimization, the shape and size of the yoke and magnetic poles are reasonably designed to make the magnetic field distribution more uniform and reduce magnetic resistance and leakage. For example, a special magnetic pole structure, such as a combination of radial magnetization and axial magnetization, is used to improve the utilization rate of the magnetic field, ensure the efficiency of magnetic force transmission between the inner and outer magnetic rotors, and thus achieve efficient operation of the pump.

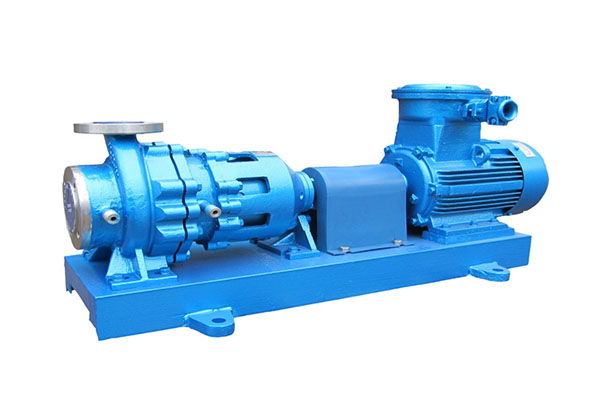

The isolation sleeve is one of the key components to achieve no leakage. It isolates the inner and outer magnetic rotors to prevent the transported fluid from contacting the outer magnetic rotor, while ensuring that the magnetic field can pass smoothly. The isolation sleeve is usually made of non-magnetic, high-strength, corrosion-resistant materials, such as titanium alloy, Hastelloy, etc. Its thickness needs to be precisely controlled. Too thick may increase magnetic field loss and affect transmission efficiency; too thin may lead to insufficient strength and easy rupture. In addition, the surface accuracy and roughness of the isolation sleeve are also strictly required to reduce fluid resistance and interference with the magnetic field.

In addition to the isolation sleeve, other parts of the pump also require reliable sealing structures to ensure no leakage. At the connection between the pump shaft and the isolation sleeve, a high-precision mechanical seal or lip seal is used to prevent fluid leakage along the axis. At the same time, sealing elements such as sealing pads and sealing rings are used at various connection parts of the pump body, and the sealing of the connection parts is ensured through reasonable fastening methods. These sealing structures work together with the magnetic transmission system to form a leak-free sealing system for the pump.

During the operation of the magnetic transmission system, a certain amount of heat will be generated due to the effect of the magnetic field and phenomena such as hysteresis and eddy current. If the heat cannot be dissipated in time, the performance of the magnet will be reduced, and even demagnetization will occur, affecting the transmission efficiency and the normal operation of the pump. Therefore, it is necessary to design an effective heat dissipation structure. Usually, a heat sink is set on the pump body or a heat dissipation method such as forced air cooling or water cooling is adopted to dissipate the heat in time, keep the magnet and other components within the appropriate operating temperature range, and ensure the stability and reliability of the magnetic transmission system.

The magnetic transmission system of the metal magnetic vortex pump achieves efficient and leak-free operation through the comprehensive design of reasonable magnetic transmission principle application, magnetic circuit design optimization, isolation sleeve and sealing structure design, heat dissipation and temperature control. These design points are interrelated and mutually influential, which jointly ensure that the metal magnetic vortex pump can work stably and reliably under various working conditions, providing safe and efficient fluid transportation solutions for industrial production and other fields.