Why is the metal magnetic centrifugal pump an ideal choice for industrial processes?

Release Time : 2025-05-20

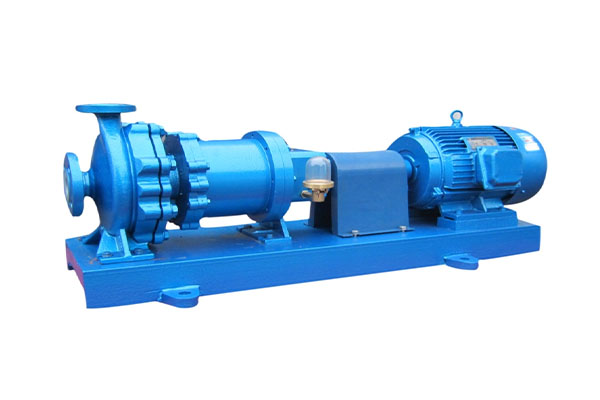

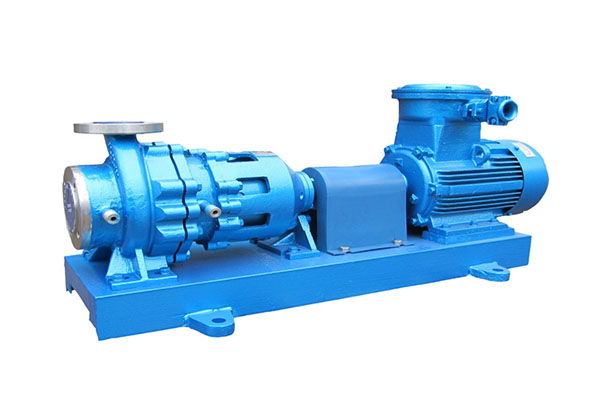

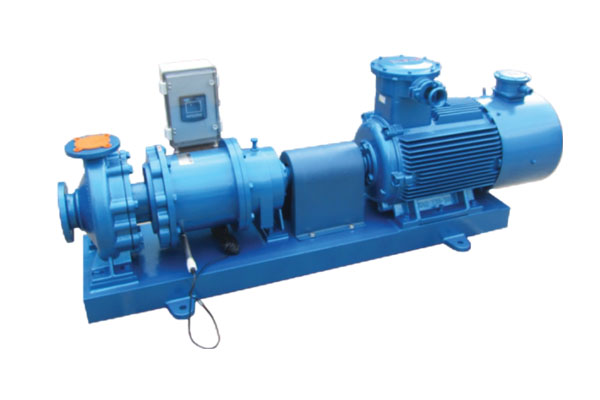

In the modern industrial field, the choice of fluid conveying equipment directly affects production efficiency, cost control and environmental protection. Especially in the case of handling corrosive media or high purity requirements, traditional pumps often cannot meet the requirements of leak-free and long-term stable operation. At this time, the metal magnetic centrifugal pump has become an ideal solution for many industries such as chemical and pharmaceutical industries with its unique advantages.

First of all, the metal magnetic centrifugal pump adopts a double cover plate and double support structure design, which greatly enhances the mechanical strength and stability of the pump. Compared with the single support structure, this design can disperse the force more evenly, reduce vibration and noise, and increase the service life of key components. This not only helps to reduce the maintenance frequency, but also ensures the reliability of the equipment in long-term operation, which is particularly important for enterprises that need continuous operation.

Another notable feature of the pump is that the impeller flow channel is finely ground and polished. In this way, the smoothness of the flow channel surface is greatly improved, thereby reducing the friction loss during liquid flow and improving the overall efficiency of the pump. In addition, this design also helps prevent particle deposition, reduces cleaning cycles, and ensures continuity and smoothness of production.

It is particularly worth mentioning that the metal magnetic centrifugal pump uses a stretched welded Hastelloy isolation sleeve and a carbon fiber filament reinforced PEEK isolation sleeve. These materials are known for their excellent corrosion resistance and high strength. Hastelloy can remain stable in extreme chemical environments, while carbon fiber reinforced PEEK is both lightweight and wear-resistant. The combination of the two makes the isolation sleeve not only effectively resist the erosion of corrosive substances such as strong acids and alkalis, but also has excellent mechanical properties, providing a solid guarantee for the safe operation of the pump.

Furthermore, the use of tungsten carbide radial bearings further highlights the high-end configuration of this pump. Tungsten carbide can maintain excellent operating conditions under high load conditions with its extremely high hardness and excellent wear resistance. This means that even in harsh working environments, the pump can work stably for a long time, greatly reducing the failure rate caused by wear, thereby reducing maintenance costs and downtime.

In addition, the metal magnetic centrifugal pump also provides jacketed and self-priming versions. The jacket design allows the temperature of the pumped medium to be precisely controlled by external heating or cooling, which is suitable for applications with strict requirements on material temperature; while the self-priming function simplifies the operation process, allowing the pump to be started without an additional water diversion device, improving the convenience of use.

In summary, the reason why the metal magnetic centrifugal pump can stand out in many industrial applications is due to its ingenious design and the excellent performance brought by the selection of high-performance materials. Whether from the perspective of improving production efficiency, reducing operating costs, or protecting the environment, it is a very worthy choice. For those companies that pursue high quality and high reliability, investing in a high-quality metal magnetic centrifugal pump is undoubtedly a wise plan for the future. It not only helps companies achieve technological upgrades, but also contributes to sustainable development.

First of all, the metal magnetic centrifugal pump adopts a double cover plate and double support structure design, which greatly enhances the mechanical strength and stability of the pump. Compared with the single support structure, this design can disperse the force more evenly, reduce vibration and noise, and increase the service life of key components. This not only helps to reduce the maintenance frequency, but also ensures the reliability of the equipment in long-term operation, which is particularly important for enterprises that need continuous operation.

Another notable feature of the pump is that the impeller flow channel is finely ground and polished. In this way, the smoothness of the flow channel surface is greatly improved, thereby reducing the friction loss during liquid flow and improving the overall efficiency of the pump. In addition, this design also helps prevent particle deposition, reduces cleaning cycles, and ensures continuity and smoothness of production.

It is particularly worth mentioning that the metal magnetic centrifugal pump uses a stretched welded Hastelloy isolation sleeve and a carbon fiber filament reinforced PEEK isolation sleeve. These materials are known for their excellent corrosion resistance and high strength. Hastelloy can remain stable in extreme chemical environments, while carbon fiber reinforced PEEK is both lightweight and wear-resistant. The combination of the two makes the isolation sleeve not only effectively resist the erosion of corrosive substances such as strong acids and alkalis, but also has excellent mechanical properties, providing a solid guarantee for the safe operation of the pump.

Furthermore, the use of tungsten carbide radial bearings further highlights the high-end configuration of this pump. Tungsten carbide can maintain excellent operating conditions under high load conditions with its extremely high hardness and excellent wear resistance. This means that even in harsh working environments, the pump can work stably for a long time, greatly reducing the failure rate caused by wear, thereby reducing maintenance costs and downtime.

In addition, the metal magnetic centrifugal pump also provides jacketed and self-priming versions. The jacket design allows the temperature of the pumped medium to be precisely controlled by external heating or cooling, which is suitable for applications with strict requirements on material temperature; while the self-priming function simplifies the operation process, allowing the pump to be started without an additional water diversion device, improving the convenience of use.

In summary, the reason why the metal magnetic centrifugal pump can stand out in many industrial applications is due to its ingenious design and the excellent performance brought by the selection of high-performance materials. Whether from the perspective of improving production efficiency, reducing operating costs, or protecting the environment, it is a very worthy choice. For those companies that pursue high quality and high reliability, investing in a high-quality metal magnetic centrifugal pump is undoubtedly a wise plan for the future. It not only helps companies achieve technological upgrades, but also contributes to sustainable development.