Why is the imc metal double leakage protection magnetic centrifugal pump a reliable choice for the chemical industry?

Release Time : 2025-06-04

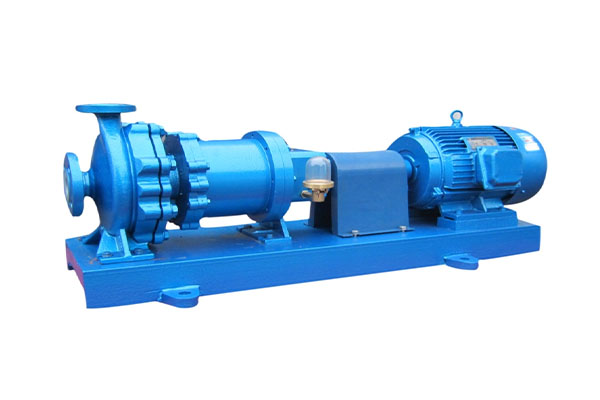

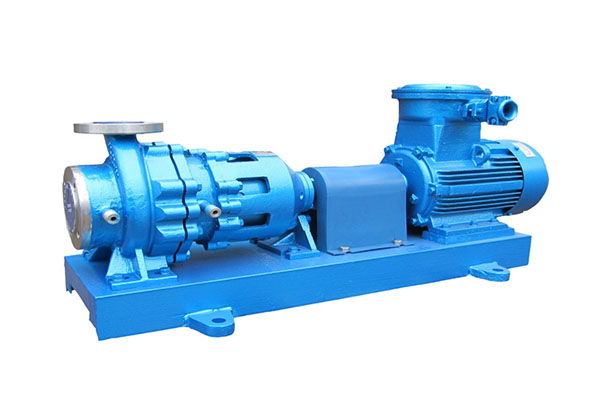

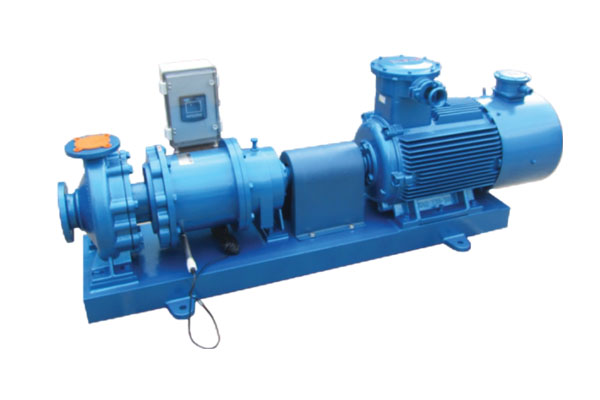

In the chemical industry, the safety and reliability of equipment are crucial when handling corrosive, toxic or flammable liquids. Any leakage may lead to serious environmental problems and economic losses, and even threaten personnel safety. The imc metal double leakage protection magnetic centrifugal pump is gradually becoming an indispensable key equipment in the chemical process with its unique design and technical features, such as double cover plate double support structure, impeller flow channel grinding and polishing, Hastelloy and carbon fiber reinforced PEEK isolation sleeve, tungsten carbide radial bearing and double protection device against leakage.

First of all, the imc metal double leakage protection magnetic centrifugal pump adopts a double cover plate double support structure, which not only enhances the overall rigidity and stability of the pump, but also significantly improves the smoothness and durability of operation. Compared with the single support structure, this design can better withstand complex working conditions and large axial and radial loads, ensuring that the pump maintains high efficiency during long-term operation. It is especially suitable for industrial scenarios that require continuous operation and high-load operation, such as fine chemical production, pharmaceutical process flow, etc.

Secondly, the imc metal double leakage protection magnetic centrifugal pump has carried out a meticulous grinding and polishing process on the impeller flow channel. This process step greatly reduces the friction loss when the fluid passes through, improves the pumping efficiency, and reduces energy consumption. The smooth flow channel surface can also effectively prevent the adhesion of solid particles and reduce the risk of clogging, which is particularly suitable for conveying media containing tiny particles. Whether it is an acid or alkali solution or a suspension, it can achieve smooth and unobstructed transmission.

Furthermore, the imc metal double leakage protection magnetic centrifugal pump uses a stretched welded Hastelloy isolation sleeve and a carbon fiber filament reinforced PEEK isolation sleeve to further improve the corrosion resistance and mechanical strength. Hastelloy is known for its excellent corrosion resistance and can work stably for a long time in extremely harsh chemical environments; while PEEK material combines high strength, wear resistance and good thermal stability. The two work together to provide a solid and reliable protective barrier for the pump and extend its service life.

In addition, the application of tungsten carbide radial bearings is also a highlight of the IMC pump. Tungsten carbide material has extremely high hardness and wear resistance, and can still maintain a low wear rate under high-speed rotation conditions, ensuring the long-term and reliable operation of the pump. Especially under heavy loads and frequent starts, tungsten carbide bearings can effectively resist impact and wear, reducing maintenance frequency and costs.

Finally, the imc metal double leakage protection magnetic centrifugal pump is equipped with a double leakage protection device, which is specially designed to deal with possible electrical safety hazards. The device can immediately cut off the power supply when an abnormal current is detected to avoid fire or other safety accidents caused by leakage. For operating sites involving hazardous chemicals, this additional safety measure undoubtedly increases the confidence and sense of security of operators.

In summary, the imc metal double leakage protection magnetic centrifugal pump has demonstrated extraordinary value in many chemical application scenarios with its advanced design concept, high-quality material selection and strict safety standards. It can not only efficiently and stably complete the transportation tasks of various complex media, but also set a new benchmark in safety, durability and environmental protection. Choosing an IMC pump is choosing an efficient, safe and sustainable future. Whether in terms of improving production efficiency, reducing operating costs, or ensuring employee health and environmental protection, this pump will bring significant benefits and long-term interests to the company.

First of all, the imc metal double leakage protection magnetic centrifugal pump adopts a double cover plate double support structure, which not only enhances the overall rigidity and stability of the pump, but also significantly improves the smoothness and durability of operation. Compared with the single support structure, this design can better withstand complex working conditions and large axial and radial loads, ensuring that the pump maintains high efficiency during long-term operation. It is especially suitable for industrial scenarios that require continuous operation and high-load operation, such as fine chemical production, pharmaceutical process flow, etc.

Secondly, the imc metal double leakage protection magnetic centrifugal pump has carried out a meticulous grinding and polishing process on the impeller flow channel. This process step greatly reduces the friction loss when the fluid passes through, improves the pumping efficiency, and reduces energy consumption. The smooth flow channel surface can also effectively prevent the adhesion of solid particles and reduce the risk of clogging, which is particularly suitable for conveying media containing tiny particles. Whether it is an acid or alkali solution or a suspension, it can achieve smooth and unobstructed transmission.

Furthermore, the imc metal double leakage protection magnetic centrifugal pump uses a stretched welded Hastelloy isolation sleeve and a carbon fiber filament reinforced PEEK isolation sleeve to further improve the corrosion resistance and mechanical strength. Hastelloy is known for its excellent corrosion resistance and can work stably for a long time in extremely harsh chemical environments; while PEEK material combines high strength, wear resistance and good thermal stability. The two work together to provide a solid and reliable protective barrier for the pump and extend its service life.

In addition, the application of tungsten carbide radial bearings is also a highlight of the IMC pump. Tungsten carbide material has extremely high hardness and wear resistance, and can still maintain a low wear rate under high-speed rotation conditions, ensuring the long-term and reliable operation of the pump. Especially under heavy loads and frequent starts, tungsten carbide bearings can effectively resist impact and wear, reducing maintenance frequency and costs.

Finally, the imc metal double leakage protection magnetic centrifugal pump is equipped with a double leakage protection device, which is specially designed to deal with possible electrical safety hazards. The device can immediately cut off the power supply when an abnormal current is detected to avoid fire or other safety accidents caused by leakage. For operating sites involving hazardous chemicals, this additional safety measure undoubtedly increases the confidence and sense of security of operators.

In summary, the imc metal double leakage protection magnetic centrifugal pump has demonstrated extraordinary value in many chemical application scenarios with its advanced design concept, high-quality material selection and strict safety standards. It can not only efficiently and stably complete the transportation tasks of various complex media, but also set a new benchmark in safety, durability and environmental protection. Choosing an IMC pump is choosing an efficient, safe and sustainable future. Whether in terms of improving production efficiency, reducing operating costs, or ensuring employee health and environmental protection, this pump will bring significant benefits and long-term interests to the company.