Is the metal magnetic vortex pump's conveying efficiency stable for media of different viscosities?

Release Time : 2025-07-28

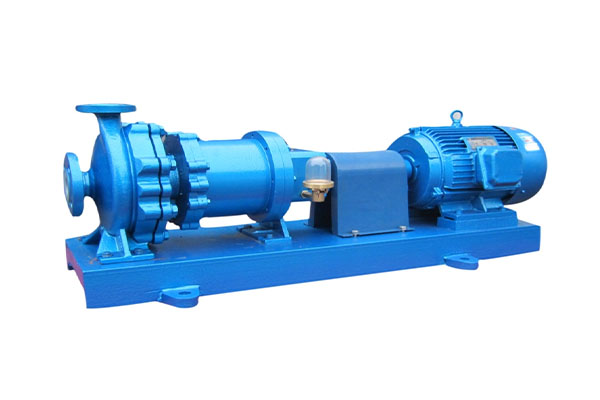

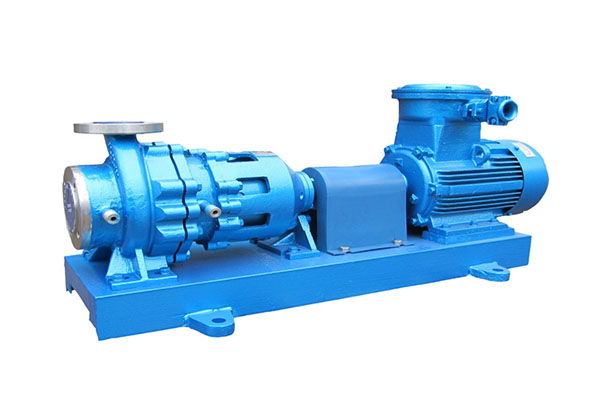

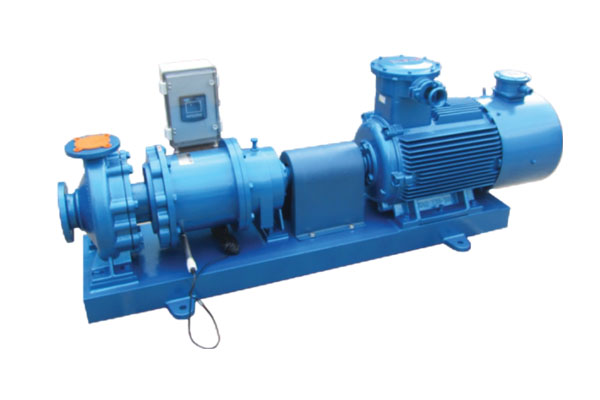

The metal magnetic vortex pump has good stability in the delivery efficiency of media with different viscosities, which is closely related to its unique working principle and structural design. It relies on the rotation of the magnetically driven vortex impeller to generate centrifugal force, so that the medium forms a stable flow trajectory in the pump chamber. This design reduces the friction loss caused by mechanical contact of traditional pumps, allowing the medium to maintain a relatively stable delivery state at different viscosities. Whether it is a low-viscosity clear water medium or an oil or slurry with a certain viscosity, the pump body can adapt to the medium characteristics through the efficient rotation of the impeller and maintain a relatively balanced delivery efficiency.

For low-viscosity media, the impeller of the metal magnetic vortex pump can quickly drive the flow of the medium when it rotates, and the centrifugal force generated by the vortex structure is sufficient to allow the medium to pass smoothly through the pump chamber, and there will be no delivery fatigue due to the medium being too thin. At this time, the medium in the pump chamber has good fluidity, the energy transfer between the impeller and the medium is efficient, and the delivery efficiency will not be significantly reduced due to low viscosity. It can stably meet the needs of continuous delivery and is suitable for the delivery of low-viscosity solvents in industries such as chemical and pharmaceutical industries.

When facing medium-viscosity media, the advantages of the metal magnetic vortex pump are more prominent. This type of medium often has a certain viscosity and is prone to resistance during transportation, but the design of the vortex impeller can form a stable pressure field through continuous rotation, gradually pushing the medium to the outlet. The gap between the impeller and the inner wall of the pump chamber has been precisely calculated, which can not only prevent the medium from being retained due to excessive viscosity, but also reduce the backflow phenomenon, ensuring that most of the medium can flow along the preset path, thereby maintaining the stability of the transportation efficiency and not fluctuating significantly due to the increase in medium viscosity.

For high-viscosity media, the metal magnetic vortex pump can also show good adaptability. Its powerful magnetic drive system provides sufficient power to overcome the large resistance generated when high-viscosity media flow. The shear force generated when the impeller rotates can appropriately reduce the apparent viscosity of the medium, allowing the medium to form an orderly flow in the pump chamber. At the same time, the metal material of the pump body has high strength and wear resistance, can withstand the additional pressure brought by high-viscosity media, avoid pump body wear or insufficient power due to excessive medium viscosity, and thus maintain a relatively stable transportation efficiency.

The sealing structure of the metal magnetic vortex pump also has a positive impact on the efficiency and stability of conveying media with different viscosities. The contactless magnetic seal design avoids the leakage problem that may occur in traditional mechanical seals. Regardless of the viscosity of the medium, it can ensure the stability of the pressure in the pump chamber and reduce the efficiency loss caused by leakage. This sealing method can also prevent the accumulation of high-viscosity media at the seal, keep the inside of the pump chamber clean, ensure that the impeller always operates in a good environment, and provide guarantee for the stable delivery of media with different viscosities.

In actual applications, the viscosity of the medium may change due to factors such as temperature and concentration, and the metal magnetic vortex pump can adapt to such changes within a certain range. When the viscosity of the medium fluctuates, its power system can maintain the stability of the impeller speed through its own adjustment ability to avoid large fluctuations in the delivery efficiency due to load changes. This adaptive ability allows it to maintain a relatively consistent delivery effect when dealing with media with complex components and unstable viscosity, meeting the requirements for continuity and stability of medium delivery in industrial production.

The metal magnetic vortex pump can maintain stable efficiency when conveying media of different viscosities due to the rationality of its structural design and the adaptability of its power system. Whether it is low-viscosity, medium-viscosity or high-viscosity media, it can reduce the impact of viscosity changes on the conveying process through optimized impeller structure, strong driving force and reliable sealing performance, providing efficient and stable solutions for media transportation in various industries, and demonstrating its practical value under complex working conditions.