What are the advantages of the carbon fiber-reinforced fluoroplastic used in the plastic double leakage protection magnetic centrifugal pump?

Release Time : 2025-08-11

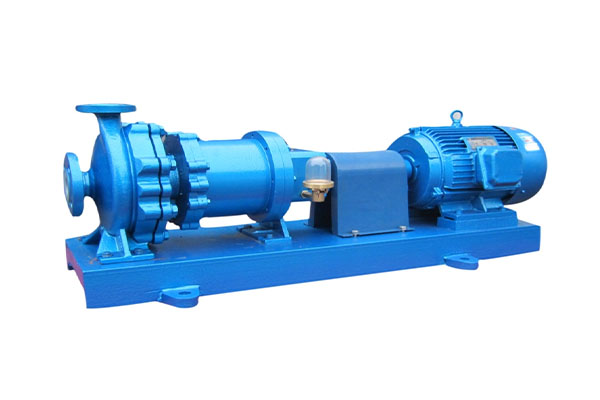

In the world of industrial pumps, the plastic double leakage protection magnetic centrifugal pump, with its unique design and superior performance, has become the preferred choice for numerous projects. This pump is more than just a simple fluid transfer tool; it is a work of art that blends modern engineering technology with aesthetics. From its exquisite exterior to its intricate internal structure, it demonstrates the designers' meticulous attention to detail and deep insight into future technological trends.

The first thing that strikes the eye is its sturdy and beautiful double cover and double support structure. This structure not only enhances the pump's overall stability but also lends the device an industrial aesthetic. The carbon steel pump body is finely polished to a discreet yet luxurious metallic luster. The steel-lined fluoroplastic interior ensures both strength and corrosion resistance. This is not only a wise choice of materials but also a commitment to environmental protection—reducing the use of hazardous substances and making the production process greener and more sustainable.

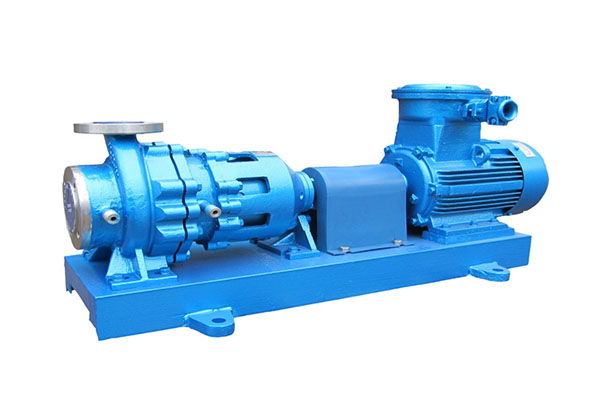

Diving deeper into the core of the plastic double leakage protection magnetic centrifugal pump reveals countless innovative highlights. For example, the use of carbon fiber-reinforced fluoroplastics gives the pump body greater strength and wear resistance, while also reducing overall weight and improving energy efficiency. The addition of a PEEK isolation sleeve further enhances the pump's resistance to high temperatures and chemical corrosion, ensuring stable operation even in extreme operating environments. The selection and application of these advanced materials not only demonstrates technological advancement but also provides users with an unprecedented user experience.

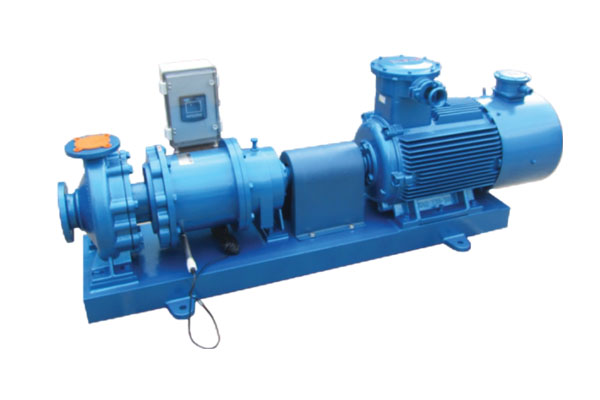

The meticulously designed silicon carbide radial bearing is as crucial as the pump's heart. Known for its exceptional hardness and wear resistance, silicon carbide effectively reduces friction and extends service life. This design not only improves pump efficiency and reduces energy loss, but also significantly lowers maintenance costs, saving users significant time and money.

Particularly noteworthy is the plastic double leakage protection magnetic centrifugal pump's dual leakage protection device. In this safety-conscious world, even the smallest details can impact the safety of the entire system. By incorporating advanced electrical protection technology, this pump minimizes accidents and ensures operator safety. This is one of the reasons why more and more companies are choosing this pump—it not only considers how to complete the work efficiently, but also prioritizes user safety.

From an aesthetic perspective, the design of the plastic double leakage protection magnetic centrifugal pump is equally stunning. Every line and every corner has been carefully considered by the designers, striving to achieve a perfect combination of function and form. The sleek contours and meticulous surface treatment embody a design philosophy that is simple yet sophisticated. It reminds us that while pursuing high performance, we should not overlook the visual appeal of the product.

The plastic double leakage protection magnetic centrifugal pump (jacketed, self-priming) is an outstanding product that combines advanced technology, high-quality materials, and user-friendly design. It not only solves various problems encountered in the use of traditional pumps, but also, through a series of innovative measures, leads a new direction for industry development.

The first thing that strikes the eye is its sturdy and beautiful double cover and double support structure. This structure not only enhances the pump's overall stability but also lends the device an industrial aesthetic. The carbon steel pump body is finely polished to a discreet yet luxurious metallic luster. The steel-lined fluoroplastic interior ensures both strength and corrosion resistance. This is not only a wise choice of materials but also a commitment to environmental protection—reducing the use of hazardous substances and making the production process greener and more sustainable.

Diving deeper into the core of the plastic double leakage protection magnetic centrifugal pump reveals countless innovative highlights. For example, the use of carbon fiber-reinforced fluoroplastics gives the pump body greater strength and wear resistance, while also reducing overall weight and improving energy efficiency. The addition of a PEEK isolation sleeve further enhances the pump's resistance to high temperatures and chemical corrosion, ensuring stable operation even in extreme operating environments. The selection and application of these advanced materials not only demonstrates technological advancement but also provides users with an unprecedented user experience.

The meticulously designed silicon carbide radial bearing is as crucial as the pump's heart. Known for its exceptional hardness and wear resistance, silicon carbide effectively reduces friction and extends service life. This design not only improves pump efficiency and reduces energy loss, but also significantly lowers maintenance costs, saving users significant time and money.

Particularly noteworthy is the plastic double leakage protection magnetic centrifugal pump's dual leakage protection device. In this safety-conscious world, even the smallest details can impact the safety of the entire system. By incorporating advanced electrical protection technology, this pump minimizes accidents and ensures operator safety. This is one of the reasons why more and more companies are choosing this pump—it not only considers how to complete the work efficiently, but also prioritizes user safety.

From an aesthetic perspective, the design of the plastic double leakage protection magnetic centrifugal pump is equally stunning. Every line and every corner has been carefully considered by the designers, striving to achieve a perfect combination of function and form. The sleek contours and meticulous surface treatment embody a design philosophy that is simple yet sophisticated. It reminds us that while pursuing high performance, we should not overlook the visual appeal of the product.

The plastic double leakage protection magnetic centrifugal pump (jacketed, self-priming) is an outstanding product that combines advanced technology, high-quality materials, and user-friendly design. It not only solves various problems encountered in the use of traditional pumps, but also, through a series of innovative measures, leads a new direction for industry development.