How do magnetic drive and jacketed designs work together to achieve leak-free conveying and precise temperature control?

Release Time : 2025-08-25

At the forefront of modern high-end fluid conveying technology, the metal magnetic split flow pump, with its combined advantages of zero leakage, high efficiency, and excellent corrosion resistance, has become a core powerhouse for demanding applications in the chemical, pharmaceutical, semiconductor, and environmental industries. The integration of jacketed and self-priming design further expands its application capabilities, enabling it to not only convey high-temperature, highly corrosive, or high-purity media but also automatically prime fluid during startup, enabling seamless integration into complex systems. More than a simple pump, it is a work of industrial art that integrates material science, precision manufacturing, and fluid dynamics, embodying the engineering philosophy of "zero pollution" and "high reliability" in silent operation.

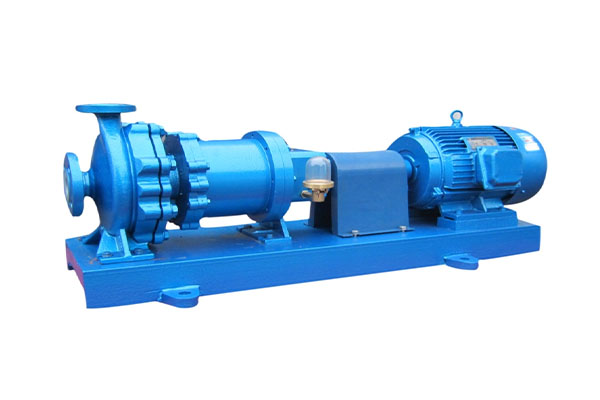

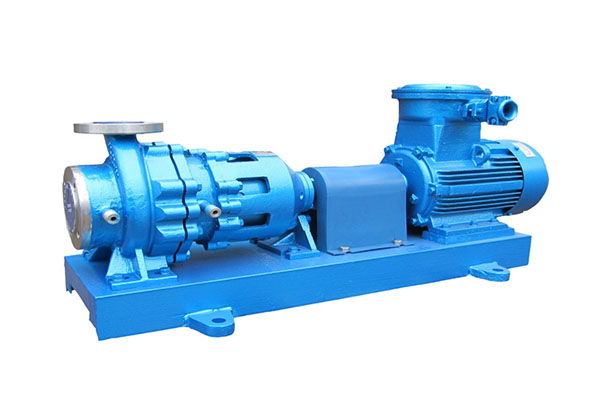

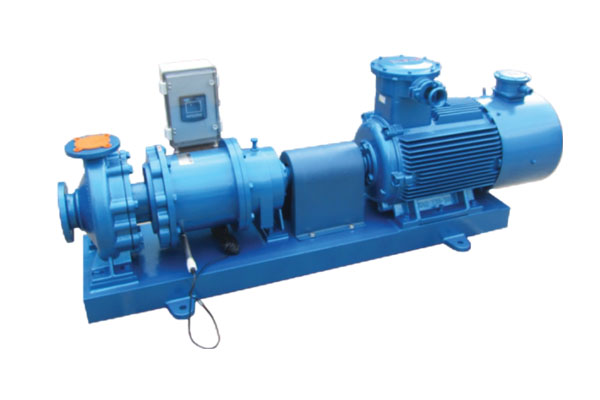

At first glance, the metal magnetic split flow pump's beauty stems from a balance of precision and strength. Its compact and sturdy overall structure, coupled with a double cover and double support design, provides the pump with exceptional rigidity and stability, effectively suppressing vibration and deformation during operation and ensuring long-term smooth operation. The sturdy lines of the casing, standard flange connections, and smooth mounting surfaces embody the rigorous order unique to industrial equipment. The pump body's surface has been meticulously polished and treated with corrosion protection, resulting in a calm and restrained metallic luster. Whether the silvery white of stainless steel or the dark gray of Hastelloy, both exude the quality and durability of high-end materials. From any angle, its symmetrical layout and compact structure embody a highly integrated engineering aesthetic, resembling a precision mechanical sculpture built for extreme environments.

The core innovation lies in the ultimate optimization of "contactless transmission" and "fully enclosed flow path." Magnetic drive technology completely eliminates the mechanical seals of traditional pumps. Power is transmitted through magnetic coupling between the inner and outer magnetic rotors, achieving a complete static seal and fundamentally eliminating the risk of leakage. This makes it particularly suitable for pumping toxic, flammable, explosive, or high-value media. The jacketed design allows for external flow of thermal oil or cooling water, precisely controlling the medium temperature to prevent crystallization, solidification, or thermal decomposition, ensuring process stability. The self-priming function, through a special impeller and pump chamber structure, automatically expels air and creates a vacuum upon startup, enabling rapid liquid priming without the need for additional priming or a foot valve, significantly improving operational convenience and system responsiveness.

From the inside out, every detail reflects the ultimate pursuit of performance. The impeller flow path is precision-ground and mirror-polished to an extremely low surface roughness. This not only significantly reduces fluid resistance and improves pump efficiency, but also prevents fluid residue and fouling within the flow path, making it particularly suitable for pumping high-purity or easily crystallizing liquids. The stretch-welded Hastelloy isolation sleeve offers excellent resistance to strong acids, bases, and chloride ion corrosion, making it an ideal barrier in extreme chemical environments. The carbon fiber filament-reinforced PEEK isolation sleeve maintains high strength while offering excellent electrical insulation and temperature resistance, making it suitable for high-voltage or high-temperature applications. The availability of these two materials demonstrates the product's high adaptability.

Even more commendable is the material innovation in key components. Tungsten carbide radial bearings are extremely hard and wear-resistant, allowing them to operate briefly without damage even in dry-running or low-lubrication conditions, significantly enhancing the pump's fault tolerance and safety. Their self-lubricating properties reduce reliance on medium lubricity and broaden their application range. The entire bearing system and magnetic rotor are located within a clean chamber outside the isolation sleeve, preventing direct contact with corrosive media and extending service life.

The metal magnetic split flow pump is a "silent guardian" of fluid systems. It uses magnetic force to overcome physical barriers and its mirror-like flow path to safeguard the purity of the medium. With every leak-free delivery and every self-priming start-up, it silently proves that true strength lies not in noisy operation but in the complete elimination of leaks and absolute adherence to process. It is more than just a pump; it symbolizes modern industry's relentless pursuit of safety, environmental protection, and efficiency.

At first glance, the metal magnetic split flow pump's beauty stems from a balance of precision and strength. Its compact and sturdy overall structure, coupled with a double cover and double support design, provides the pump with exceptional rigidity and stability, effectively suppressing vibration and deformation during operation and ensuring long-term smooth operation. The sturdy lines of the casing, standard flange connections, and smooth mounting surfaces embody the rigorous order unique to industrial equipment. The pump body's surface has been meticulously polished and treated with corrosion protection, resulting in a calm and restrained metallic luster. Whether the silvery white of stainless steel or the dark gray of Hastelloy, both exude the quality and durability of high-end materials. From any angle, its symmetrical layout and compact structure embody a highly integrated engineering aesthetic, resembling a precision mechanical sculpture built for extreme environments.

The core innovation lies in the ultimate optimization of "contactless transmission" and "fully enclosed flow path." Magnetic drive technology completely eliminates the mechanical seals of traditional pumps. Power is transmitted through magnetic coupling between the inner and outer magnetic rotors, achieving a complete static seal and fundamentally eliminating the risk of leakage. This makes it particularly suitable for pumping toxic, flammable, explosive, or high-value media. The jacketed design allows for external flow of thermal oil or cooling water, precisely controlling the medium temperature to prevent crystallization, solidification, or thermal decomposition, ensuring process stability. The self-priming function, through a special impeller and pump chamber structure, automatically expels air and creates a vacuum upon startup, enabling rapid liquid priming without the need for additional priming or a foot valve, significantly improving operational convenience and system responsiveness.

From the inside out, every detail reflects the ultimate pursuit of performance. The impeller flow path is precision-ground and mirror-polished to an extremely low surface roughness. This not only significantly reduces fluid resistance and improves pump efficiency, but also prevents fluid residue and fouling within the flow path, making it particularly suitable for pumping high-purity or easily crystallizing liquids. The stretch-welded Hastelloy isolation sleeve offers excellent resistance to strong acids, bases, and chloride ion corrosion, making it an ideal barrier in extreme chemical environments. The carbon fiber filament-reinforced PEEK isolation sleeve maintains high strength while offering excellent electrical insulation and temperature resistance, making it suitable for high-voltage or high-temperature applications. The availability of these two materials demonstrates the product's high adaptability.

Even more commendable is the material innovation in key components. Tungsten carbide radial bearings are extremely hard and wear-resistant, allowing them to operate briefly without damage even in dry-running or low-lubrication conditions, significantly enhancing the pump's fault tolerance and safety. Their self-lubricating properties reduce reliance on medium lubricity and broaden their application range. The entire bearing system and magnetic rotor are located within a clean chamber outside the isolation sleeve, preventing direct contact with corrosive media and extending service life.

The metal magnetic split flow pump is a "silent guardian" of fluid systems. It uses magnetic force to overcome physical barriers and its mirror-like flow path to safeguard the purity of the medium. With every leak-free delivery and every self-priming start-up, it silently proves that true strength lies not in noisy operation but in the complete elimination of leaks and absolute adherence to process. It is more than just a pump; it symbolizes modern industry's relentless pursuit of safety, environmental protection, and efficiency.