Are the flow-through components of the metal magnetic vortex pump truly corrosion-resistant?

Release Time : 2025-09-08

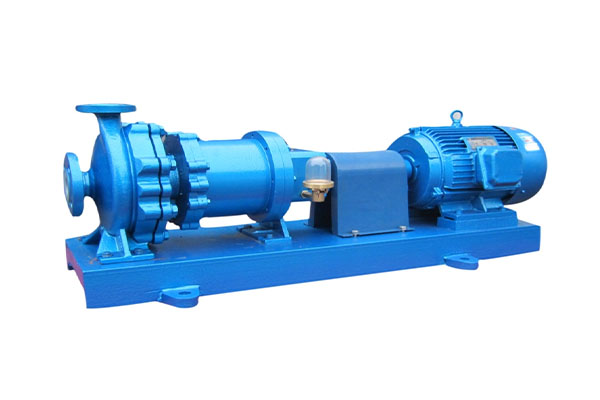

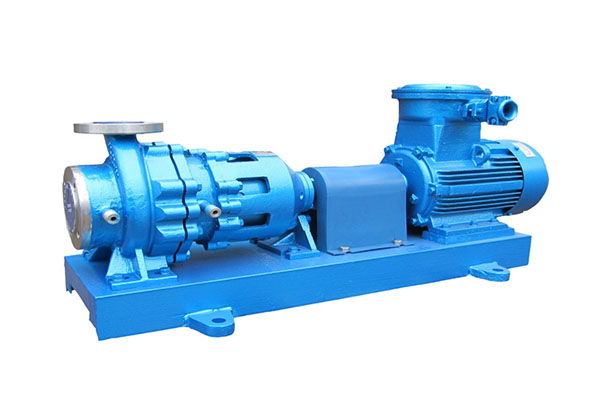

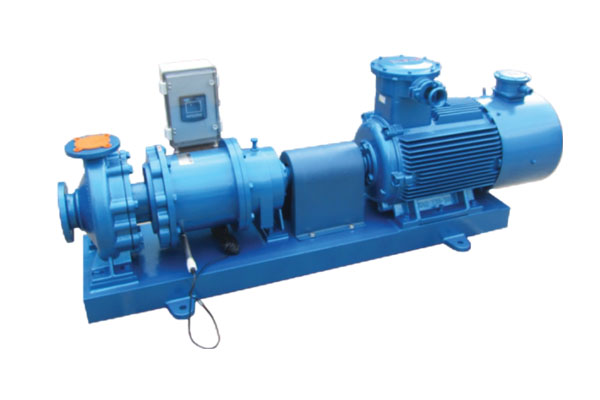

In high-end industrial fields like chemical processing, electroplating, semiconductors, pharmaceuticals, and even new energy battery manufacturing, fluid transportation is never a simple "get from A to B" process; it demands a comprehensive test of material limits, process purity, and system safety. Strong acids like sulfuric acid and hydrochloric acid, strong bases like sodium hydroxide solution, organic solvents like acetone and DMF, and even halogen-containing or highly oxidizing etching solutions all flow silently through pipelines. A single misstep can corrode equipment, contaminate products, harm the environment, and even cause safety incidents. One of the core strengths of the metal magnetic vortex pump's status as a critical piece of equipment in these demanding environments lies in its truly all-metal corrosion-resistant flow-through components. This isn't just a technical description; it's a silent declaration of war against chemical attacks and a solemn commitment to process purity.

The term "flow-through components" refers to all parts of the pump body that come into direct contact with the pumped fluid: the pump casing, impeller (or scroll disk), inlet and outlet flanges, liner, and bushing. In traditional centrifugal or gear pumps, these components are often made of cast iron, carbon steel, or ordinary stainless steel. While adequate for mild media, they quickly rust, pierce, and fail when exposed to highly corrosive fluids, like thin ice meeting fire. Metal magnetic vortex pumps, on the other hand, completely eliminate compromises and utilize high-grade, corrosion-resistant metals such as Hastelloy, titanium alloy, special duplex stainless steel, tantalum, or zirconium, building a defense from the very beginning. These metals are not only extremely chemically inert but also form a dense passivation film on their microstructures. Even under extreme operating conditions of high temperature, high pressure, and high concentration, they effectively block isolator penetration, slowing the corrosion process and ensuring the pump remains rock-solid despite the ravages of time.

The significance of the all-metal construction lies in eliminating the contamination risks associated with non-metallic materials. In semiconductor wet processing or biopharmaceutical processes, even a fraction of a millionth of an impurity can render a wafer scrapped or a drug ineffective. While plastic, rubber, or ceramic linings offer some corrosion resistance, they can still release particles, plasticizers, or ions under prolonged friction, temperature cycling, or solvent immersion, potentially contaminating high-purity fluids. All-metal construction, with its precision-polished or specially passivated surface, is porosity-free, non-sludge-free, and non-leaching-resistant. It acts like a "chemically inert container," allowing fluids to flow freely, free of dust and impurities, safeguarding the pristine purity of every drop.

Corrosion resistance isn't a static property; it's a dynamic process. Fluctuations in fluid concentration, sudden temperature changes, start-up and shutdown shocks, and cavitation all accelerate material degradation. The designers of the Metal Magnetic Vortex Pump are well aware of this, pursuing meticulous material selection and meticulous structural design. Smooth flow paths with no dead corners prevent fluid stagnation and localized concentration corrosion. Wall thickness is uniform and stress-free, minimizing the risk of intergranular corrosion. Joints utilize metal-to-metal seals or specialized welding to prevent leaks from gasket aging. The pump's vortex structure inherently reduces high-speed shear and turbulence, minimizing mechanical erosion on the metal surface and ensuring long-lasting corrosion resistance.

With the added benefit of magnetic drive, the advantages of this all-metal corrosion-resistant design are even more pronounced. The elimination of mechanical seals completely eliminates the friction between the seal faces, a traditionally high-risk area for corrosion and leakage. Power is transmitted via a magnetic field through a metal isolation sleeve, eliminating physical contact between the inner and outer magnetic rotors. The medium is completely enclosed within the metal chamber, achieving absolute isolation: "no medium exiting the pump, no external environment entering." This ensures absolute safety even when handling highly toxic, flammable, explosive, or radioactive liquids.

From an operational and maintenance perspective, all-metal corrosion resistance means a longer service life and reduced replacement frequency. Without the need for frequent downtime to replace corroded impellers or pump casings, or the worry of unexpected leaks leading to production halts and environmental incidents, companies can focus on production rather than equipment repairs. For production lines transporting valuable chemicals or critical process fluids, this reliability translates directly into cost savings and guaranteed production capacity.

In summary, the answer to the question of whether the metal magnetic vortex pump's flow-through components are all-metal and corrosion-resistant is not simply "yes." Rather, it utilizes high-grade metal as a shield, precision structure as armor, and magnetic isolation as a spearhead, carving out a safe, clean, and durable conveying channel amidst the rigors of chemical engineering. Unassuming, it carries the core lifeblood of the process; silently, it safeguards the product's pure quality. Deep within those unseen pipes, its metal body silently fights against the ravages of corrosion, allowing dangerous fluids to flow docilely and ensuring the safe progress of precision manufacturing. This is another expression of the beauty of industry and the most fundamental interpretation of the word "reliability" in modern engineering.

The term "flow-through components" refers to all parts of the pump body that come into direct contact with the pumped fluid: the pump casing, impeller (or scroll disk), inlet and outlet flanges, liner, and bushing. In traditional centrifugal or gear pumps, these components are often made of cast iron, carbon steel, or ordinary stainless steel. While adequate for mild media, they quickly rust, pierce, and fail when exposed to highly corrosive fluids, like thin ice meeting fire. Metal magnetic vortex pumps, on the other hand, completely eliminate compromises and utilize high-grade, corrosion-resistant metals such as Hastelloy, titanium alloy, special duplex stainless steel, tantalum, or zirconium, building a defense from the very beginning. These metals are not only extremely chemically inert but also form a dense passivation film on their microstructures. Even under extreme operating conditions of high temperature, high pressure, and high concentration, they effectively block isolator penetration, slowing the corrosion process and ensuring the pump remains rock-solid despite the ravages of time.

The significance of the all-metal construction lies in eliminating the contamination risks associated with non-metallic materials. In semiconductor wet processing or biopharmaceutical processes, even a fraction of a millionth of an impurity can render a wafer scrapped or a drug ineffective. While plastic, rubber, or ceramic linings offer some corrosion resistance, they can still release particles, plasticizers, or ions under prolonged friction, temperature cycling, or solvent immersion, potentially contaminating high-purity fluids. All-metal construction, with its precision-polished or specially passivated surface, is porosity-free, non-sludge-free, and non-leaching-resistant. It acts like a "chemically inert container," allowing fluids to flow freely, free of dust and impurities, safeguarding the pristine purity of every drop.

Corrosion resistance isn't a static property; it's a dynamic process. Fluctuations in fluid concentration, sudden temperature changes, start-up and shutdown shocks, and cavitation all accelerate material degradation. The designers of the Metal Magnetic Vortex Pump are well aware of this, pursuing meticulous material selection and meticulous structural design. Smooth flow paths with no dead corners prevent fluid stagnation and localized concentration corrosion. Wall thickness is uniform and stress-free, minimizing the risk of intergranular corrosion. Joints utilize metal-to-metal seals or specialized welding to prevent leaks from gasket aging. The pump's vortex structure inherently reduces high-speed shear and turbulence, minimizing mechanical erosion on the metal surface and ensuring long-lasting corrosion resistance.

With the added benefit of magnetic drive, the advantages of this all-metal corrosion-resistant design are even more pronounced. The elimination of mechanical seals completely eliminates the friction between the seal faces, a traditionally high-risk area for corrosion and leakage. Power is transmitted via a magnetic field through a metal isolation sleeve, eliminating physical contact between the inner and outer magnetic rotors. The medium is completely enclosed within the metal chamber, achieving absolute isolation: "no medium exiting the pump, no external environment entering." This ensures absolute safety even when handling highly toxic, flammable, explosive, or radioactive liquids.

From an operational and maintenance perspective, all-metal corrosion resistance means a longer service life and reduced replacement frequency. Without the need for frequent downtime to replace corroded impellers or pump casings, or the worry of unexpected leaks leading to production halts and environmental incidents, companies can focus on production rather than equipment repairs. For production lines transporting valuable chemicals or critical process fluids, this reliability translates directly into cost savings and guaranteed production capacity.

In summary, the answer to the question of whether the metal magnetic vortex pump's flow-through components are all-metal and corrosion-resistant is not simply "yes." Rather, it utilizes high-grade metal as a shield, precision structure as armor, and magnetic isolation as a spearhead, carving out a safe, clean, and durable conveying channel amidst the rigors of chemical engineering. Unassuming, it carries the core lifeblood of the process; silently, it safeguards the product's pure quality. Deep within those unseen pipes, its metal body silently fights against the ravages of corrosion, allowing dangerous fluids to flow docilely and ensuring the safe progress of precision manufacturing. This is another expression of the beauty of industry and the most fundamental interpretation of the word "reliability" in modern engineering.