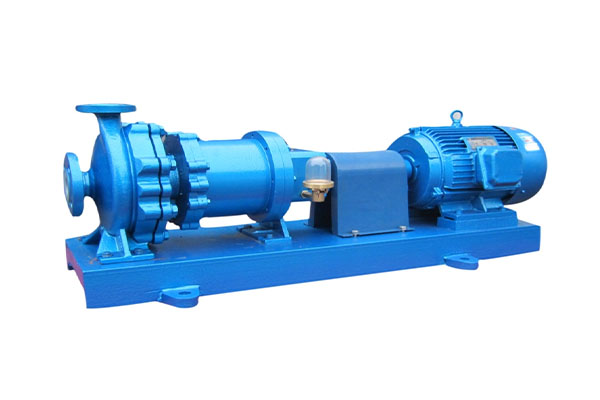

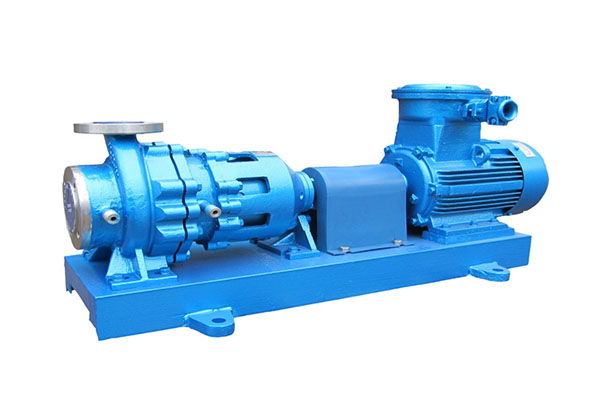

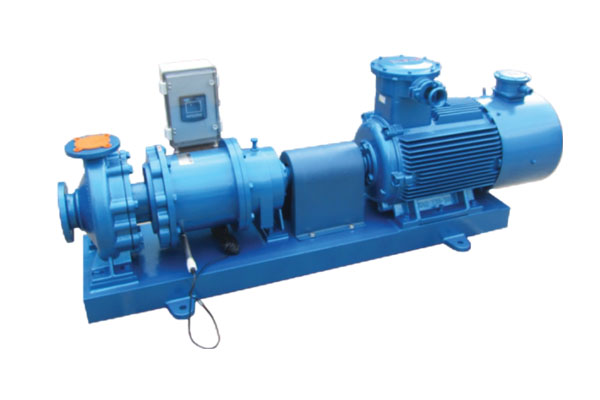

Does a metal magnetic vortex pump achieve complete leak-free operation?

Release Time : 2025-11-03

In industrial fluid transport systems, the sealing performance of a pump directly affects production safety, environmental protection, and equipment lifespan. Traditional pumps generally rely on mechanical seals or packing seals to prevent media leakage. However, these dynamic seal structures inevitably face problems such as wear, aging, dry running, or crystallization jamming during long-term operation. Once they fail, they can cause material loss or even leakage accidents, threatening personnel health and environmental safety. Especially when transporting highly corrosive, toxic, flammable, or high-purity liquids, even a small leak can have serious consequences. Against this backdrop, does a metal magnetic vortex pump achieve complete leak-free operation? The answer is yes—through a revolutionary magnetic drive principle, it fundamentally eliminates the hidden dangers of traditional seals, achieving true "zero leakage."

The core of the metal magnetic vortex pump lies in its contactless power transmission mechanism. It abandons the traditional rotating shaft and mechanical seal structure that penetrates the pump body, replacing it with a magnetic coupling system composed of inner and outer magnetic rotors. The motor drives the outer magnetic rotor to rotate, and the magnetic field it generates passes through the sealed isolation sleeve, causing the inner magnetic rotor to rotate synchronously, thereby driving the impeller to perform work. Throughout the process, the pump chamber is completely separated from the external power source by a single, complete metal isolation sleeve, forming a fully enclosed static seal. Since no rotating shaft passes through the pump casing, there are no dynamic sealing points in the traditional sense, completely eliminating leakage paths caused by seal wear.

This design not only solves the leakage problem but also greatly improves the system's safety and reliability. When conveying hydrochloric acid, sulfuric acid, hydrofluoric acid, organic solvents, or toxic chemicals, even if the medium is highly corrosive or volatile, it can be completely sealed inside the pump chamber, preventing contact with the external environment. Operators do not need to worry about splashing or gas escape caused by sudden seal failure, and maintenance personnel do not need to frequently replace sealing components, reducing operational risks and labor costs.

More importantly, the sealing isolation sleeve of the metal magnetic vortex pump is typically made of highly corrosion-resistant metal materials, such as Hastelloy, titanium alloy, or stainless steel, and undergoes precision welding and non-destructive testing to ensure its strength and integrity. This insulating sleeve serves as both a channel for magnetic force transmission and the first line of defense against high pressure and corrosion. It does not participate in movement and is unaffected by friction. Provided the material is correctly selected, it can remain stable during long-term operation, unlike mechanical seals which require regular maintenance or replacement.

Furthermore, due to the absence of a mechanical seal, the pump does not require an additional seal flushing system or cooling water support during startup and operation, simplifying auxiliary piping configuration and reducing potential leakage points. Even under dry running or brief idling conditions, it will not be immediately damaged by seal dry running, exhibiting stronger adaptability to various operating conditions.

In applications requiring high purity or cleanliness, such as electronic chemical transportation, pharmaceutical processes, or semiconductor cleaning, the advantages of metal magnetic vortex pumps are equally significant. Traditional seals may affect the purity of the medium due to the precipitation of tiny particles or lubricant contamination, while the all-metal enclosed flow channel and contamination-free transmission method of metal magnetic vortex pumps ensure the cleanliness and purity of the transported medium, meeting stringent process standards.

Of course, this "leak-free" performance is not based on luck, but rather on a systematic guarantee built upon rigorous physical principles and precision manufacturing. From magnetic circuit design to material matching, from eddy current loss control to thermal management, every step serves the core objectives of safety and stability.

In summary, the metal magnetic vortex pump, by replacing traditional shaft seals with magnetic coupling, achieves a completely leak-free operating mode. This is not only a technological evolution but also a redefinition of safety principles. Behind every silent operation lies industrial civilization's unwavering commitment to the pursuit of "zero risk," allowing hazardous media to flow safely in confined spaces and safeguarding every inch of the production site.

The core of the metal magnetic vortex pump lies in its contactless power transmission mechanism. It abandons the traditional rotating shaft and mechanical seal structure that penetrates the pump body, replacing it with a magnetic coupling system composed of inner and outer magnetic rotors. The motor drives the outer magnetic rotor to rotate, and the magnetic field it generates passes through the sealed isolation sleeve, causing the inner magnetic rotor to rotate synchronously, thereby driving the impeller to perform work. Throughout the process, the pump chamber is completely separated from the external power source by a single, complete metal isolation sleeve, forming a fully enclosed static seal. Since no rotating shaft passes through the pump casing, there are no dynamic sealing points in the traditional sense, completely eliminating leakage paths caused by seal wear.

This design not only solves the leakage problem but also greatly improves the system's safety and reliability. When conveying hydrochloric acid, sulfuric acid, hydrofluoric acid, organic solvents, or toxic chemicals, even if the medium is highly corrosive or volatile, it can be completely sealed inside the pump chamber, preventing contact with the external environment. Operators do not need to worry about splashing or gas escape caused by sudden seal failure, and maintenance personnel do not need to frequently replace sealing components, reducing operational risks and labor costs.

More importantly, the sealing isolation sleeve of the metal magnetic vortex pump is typically made of highly corrosion-resistant metal materials, such as Hastelloy, titanium alloy, or stainless steel, and undergoes precision welding and non-destructive testing to ensure its strength and integrity. This insulating sleeve serves as both a channel for magnetic force transmission and the first line of defense against high pressure and corrosion. It does not participate in movement and is unaffected by friction. Provided the material is correctly selected, it can remain stable during long-term operation, unlike mechanical seals which require regular maintenance or replacement.

Furthermore, due to the absence of a mechanical seal, the pump does not require an additional seal flushing system or cooling water support during startup and operation, simplifying auxiliary piping configuration and reducing potential leakage points. Even under dry running or brief idling conditions, it will not be immediately damaged by seal dry running, exhibiting stronger adaptability to various operating conditions.

In applications requiring high purity or cleanliness, such as electronic chemical transportation, pharmaceutical processes, or semiconductor cleaning, the advantages of metal magnetic vortex pumps are equally significant. Traditional seals may affect the purity of the medium due to the precipitation of tiny particles or lubricant contamination, while the all-metal enclosed flow channel and contamination-free transmission method of metal magnetic vortex pumps ensure the cleanliness and purity of the transported medium, meeting stringent process standards.

Of course, this "leak-free" performance is not based on luck, but rather on a systematic guarantee built upon rigorous physical principles and precision manufacturing. From magnetic circuit design to material matching, from eddy current loss control to thermal management, every step serves the core objectives of safety and stability.

In summary, the metal magnetic vortex pump, by replacing traditional shaft seals with magnetic coupling, achieves a completely leak-free operating mode. This is not only a technological evolution but also a redefinition of safety principles. Behind every silent operation lies industrial civilization's unwavering commitment to the pursuit of "zero risk," allowing hazardous media to flow safely in confined spaces and safeguarding every inch of the production site.