How can IMC metal magnetic centrifugal pumps maintain high strength while reducing eddy current losses and improving energy efficiency?

Release Time : 2025-10-21

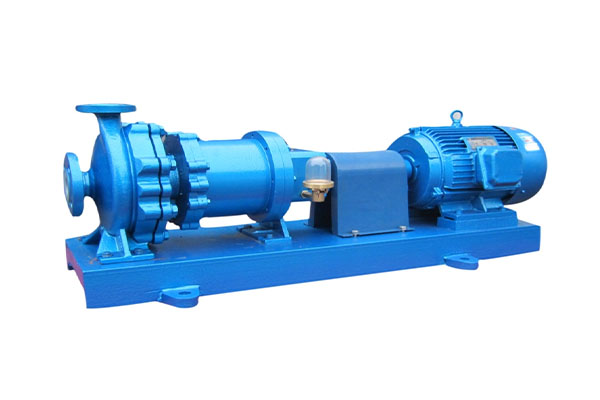

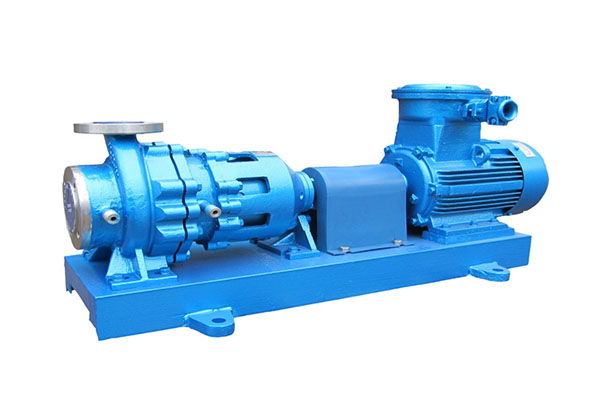

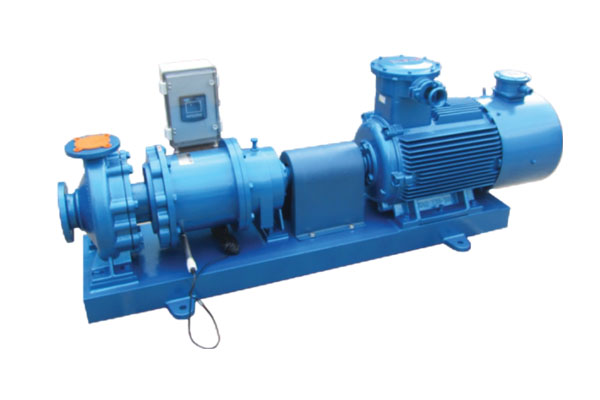

Magnetic centrifugal pumps, as critical equipment for leak-free transport of hazardous and corrosive media, are widely used in high-end industries such as the chemical, pharmaceutical, petrochemical, and semiconductor industries. IMC metal magnetic centrifugal pumps are the preferred choice for demanding operating conditions due to their excellent mechanical strength, resistance to high temperatures and pressures, and corrosion resistance. However, while metal materials offer structural reliability, they also present a long-standing technical challenge plaguing the industry: eddy current losses. When the alternating magnetic field generated by permanent magnets penetrates the metal isolation sleeve, it induces a circular current within the sleeve, dissipating energy as heat. This not only reduces pump transmission efficiency but can also cause overheating, demagnetization, and even equipment damage. Therefore, effectively reducing eddy current losses while maintaining the high strength of the metal casing has become a core technical challenge in improving the energy efficiency and reliability of magnetic pumps.

1. Causes and Impacts of Eddy Current Losses

In a magnetic pump, the prime mover rotates the inner magnetic rotor via an outer magnetic rotor. The two are separated by a sealed isolation sleeve, achieving a "dynamic seal transformed into a static seal." When the permanent magnets of the outer magnetic rotor rotate, their magnetic fields periodically cut through the metal isolation sleeve. According to Faraday's law of electromagnetic induction, this generates closed-loop induced currents—eddy currents—in the conductive material. This current does no useful work, but instead converts into Joule heat, resulting in energy loss. Experiments have shown that in traditional thick-walled metal isolation sleeves, eddy current losses can account for 5% to 15% of the total pump input power, and even higher in severe cases. This not only reduces system energy efficiency but also causes a sharp rise in isolation sleeve temperature, potentially causing the permanent magnets' operating temperature to exceed the Curie point and irreversible demagnetization, directly threatening the pump's safe operation.

2. Optimizing Isolation Sleeve Materials: Using High-Resistivity Alloys

The most fundamental way to reduce eddy currents is to increase the material's resistivity, thereby reducing the induced current. Traditional 304 and 316 stainless steels, while strong, also have relatively good conductivity and high eddy current losses. Modern high-performance IMC metal magnetic drive pumps use high-resistivity specialty alloys, such as Hastelloy, titanium, or Inconel, as isolation sleeve materials. These materials not only offer excellent corrosion resistance and mechanical strength, but also possess resistivity far higher than that of ordinary stainless steel, significantly suppressing eddy current generation. Furthermore, these alloys maintain excellent mechanical properties even at high temperatures, ensuring the pump's structural integrity under high-pressure, high-temperature conditions.

3. Reducing the Wall Thickness of the Isolation Sleeve: Geometric Optimization Reduces Losses

Eddy current losses are proportional to the square of the isolation sleeve wall thickness. Therefore, minimizing the thickness of the isolation sleeve while meeting pressure vessel design specifications is an effective way to reduce losses. Modern IMC pumps use finite element analysis to simulate stress on the isolation sleeve, accurately calculating its strength limit at maximum operating pressure. This allows the wall thickness to be controlled between 0.4 and 0.8 mm while ensuring a safety factor. The ultra-thin wall design significantly reduces the conductor volume, significantly reducing the total amount of eddy currents. Furthermore, high-precision machining processes ensure the roundness and uniformity of the thin-wall structure, avoiding localized stress concentrations.

4. Optimizing the Magnetic Circuit Design: Reducing the Magnetic Field Variation Rate

In addition to improving the isolation sleeve, the overall magnetic circuit design of the pump is also undergoing continuous optimization. Axial magnetization or multi-pole synchronous magnet structures achieve more uniform magnetic field distribution, reduce sudden magnetic field gradients, and thus lower the induced electromotive force. Some high-end models also incorporate segmented magnets or non-magnetic support rings to further reduce the impact of stray magnetic fields on the centrifugal sleeve. Furthermore, the air gap between the inner and outer magnetic rotors is optimally matched to ensure sufficient torque transmission while preventing excessive magnetic field penetration, achieving a balance between efficiency and safety.

5. Integrated Cooling System: Active Heat Dissipation Ensures Stable Operation

Even with multiple loss-reduction measures, a small amount of heat is still generated. To address this, IMC pumps are typically designed with internal cooling channels, using the pumped medium or external coolant to forcefully cool the centrifugal sleeve area, promptly removing heat and preventing temperature accumulation. Some models also feature temperature sensors for overheating warnings and automatic protection, comprehensively enhancing system reliability.

IMC metal magnetic centrifugal pumps utilize multiple technical measures, including the use of high-resistivity alloys, reduced centrifugal sleeve wall thickness, optimized magnetic circuit structure, and an integrated cooling system. While maintaining high strength and sealing, IMC pumps effectively suppress eddy current losses, significantly improving transmission efficiency and operational stability. The comprehensive energy efficiency of modern IMC metal magnetic pumps is close to that of traditional mechanical seal pumps, while achieving true "zero leakage", making them an ideal choice for high-end process industries that combine safety, reliability and energy saving.

1. Causes and Impacts of Eddy Current Losses

In a magnetic pump, the prime mover rotates the inner magnetic rotor via an outer magnetic rotor. The two are separated by a sealed isolation sleeve, achieving a "dynamic seal transformed into a static seal." When the permanent magnets of the outer magnetic rotor rotate, their magnetic fields periodically cut through the metal isolation sleeve. According to Faraday's law of electromagnetic induction, this generates closed-loop induced currents—eddy currents—in the conductive material. This current does no useful work, but instead converts into Joule heat, resulting in energy loss. Experiments have shown that in traditional thick-walled metal isolation sleeves, eddy current losses can account for 5% to 15% of the total pump input power, and even higher in severe cases. This not only reduces system energy efficiency but also causes a sharp rise in isolation sleeve temperature, potentially causing the permanent magnets' operating temperature to exceed the Curie point and irreversible demagnetization, directly threatening the pump's safe operation.

2. Optimizing Isolation Sleeve Materials: Using High-Resistivity Alloys

The most fundamental way to reduce eddy currents is to increase the material's resistivity, thereby reducing the induced current. Traditional 304 and 316 stainless steels, while strong, also have relatively good conductivity and high eddy current losses. Modern high-performance IMC metal magnetic drive pumps use high-resistivity specialty alloys, such as Hastelloy, titanium, or Inconel, as isolation sleeve materials. These materials not only offer excellent corrosion resistance and mechanical strength, but also possess resistivity far higher than that of ordinary stainless steel, significantly suppressing eddy current generation. Furthermore, these alloys maintain excellent mechanical properties even at high temperatures, ensuring the pump's structural integrity under high-pressure, high-temperature conditions.

3. Reducing the Wall Thickness of the Isolation Sleeve: Geometric Optimization Reduces Losses

Eddy current losses are proportional to the square of the isolation sleeve wall thickness. Therefore, minimizing the thickness of the isolation sleeve while meeting pressure vessel design specifications is an effective way to reduce losses. Modern IMC pumps use finite element analysis to simulate stress on the isolation sleeve, accurately calculating its strength limit at maximum operating pressure. This allows the wall thickness to be controlled between 0.4 and 0.8 mm while ensuring a safety factor. The ultra-thin wall design significantly reduces the conductor volume, significantly reducing the total amount of eddy currents. Furthermore, high-precision machining processes ensure the roundness and uniformity of the thin-wall structure, avoiding localized stress concentrations.

4. Optimizing the Magnetic Circuit Design: Reducing the Magnetic Field Variation Rate

In addition to improving the isolation sleeve, the overall magnetic circuit design of the pump is also undergoing continuous optimization. Axial magnetization or multi-pole synchronous magnet structures achieve more uniform magnetic field distribution, reduce sudden magnetic field gradients, and thus lower the induced electromotive force. Some high-end models also incorporate segmented magnets or non-magnetic support rings to further reduce the impact of stray magnetic fields on the centrifugal sleeve. Furthermore, the air gap between the inner and outer magnetic rotors is optimally matched to ensure sufficient torque transmission while preventing excessive magnetic field penetration, achieving a balance between efficiency and safety.

5. Integrated Cooling System: Active Heat Dissipation Ensures Stable Operation

Even with multiple loss-reduction measures, a small amount of heat is still generated. To address this, IMC pumps are typically designed with internal cooling channels, using the pumped medium or external coolant to forcefully cool the centrifugal sleeve area, promptly removing heat and preventing temperature accumulation. Some models also feature temperature sensors for overheating warnings and automatic protection, comprehensively enhancing system reliability.

IMC metal magnetic centrifugal pumps utilize multiple technical measures, including the use of high-resistivity alloys, reduced centrifugal sleeve wall thickness, optimized magnetic circuit structure, and an integrated cooling system. While maintaining high strength and sealing, IMC pumps effectively suppress eddy current losses, significantly improving transmission efficiency and operational stability. The comprehensive energy efficiency of modern IMC metal magnetic pumps is close to that of traditional mechanical seal pumps, while achieving true "zero leakage", making them an ideal choice for high-end process industries that combine safety, reliability and energy saving.