How do metal magnetic gear pumps balance magnetic field penetration and structural strength?

Release Time : 2025-10-09

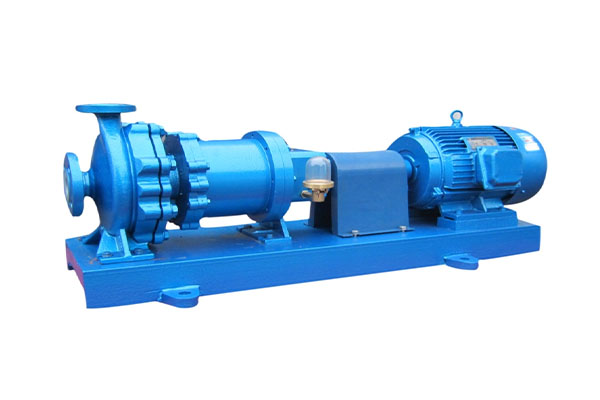

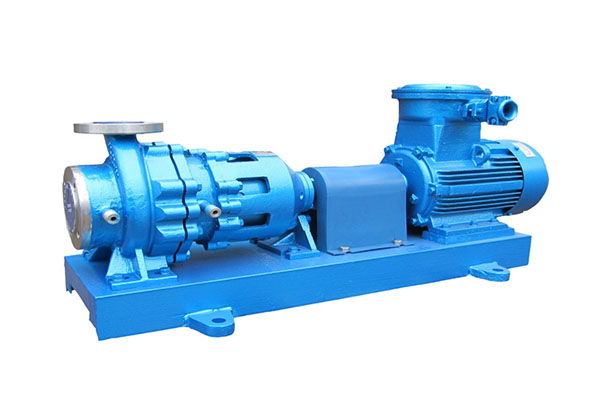

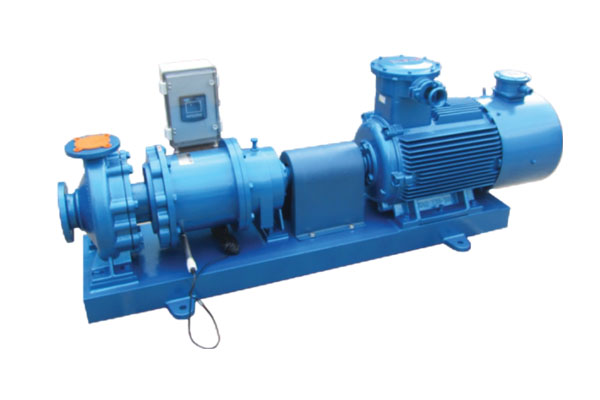

As leak-free, highly reliable fluid conveying equipment, metal magnetic gear pumps are widely used in industries such as the chemical, pharmaceutical, and nuclear industries, where sealing is crucial. Their core principle is to transmit power through magnetic coupling, eliminating the dynamic seals of traditional pumps and completely eliminating the risk of leakage. However, a key technical challenge during the design and manufacturing process is how to ensure efficient magnetic field penetration for stable power transmission while ensuring sufficient structural strength of key components such as the isolation sleeve to withstand operating pressure, temperature fluctuations, and corrosive environments. This conflicting balance directly determines the pump's performance, lifespan, and safety.

1. Magnetic Field Penetration: The Core Requirement for Efficient Power Transmission

In a magnetic gear pump, power is transmitted through magnetic coupling between the outer and inner magnetic rotors. A metal isolation sleeve separates the two, completely sealing the pump chamber from the outside world. The magnetic field must penetrate this isolation sleeve to drive the inner magnetic rotor and the gears. Therefore, the magnetic permeability and thickness of the isolation sleeve material directly affect the efficiency of magnetic power transmission. Ideally, the isolation sleeve should be as thin as possible and made of low-permeability material to reduce magnetic resistance, enhance torque transmission, and minimize eddy current losses and temperature rise. However, an excessively thin isolation sleeve weakens its mechanical strength, making it unable to withstand the stresses of high-pressure operating conditions. Especially under high temperature, high pressure, or high speed conditions, the isolation sleeve may bulge, suffer fatigue cracks, or even rupture due to the internal and external pressure differential, leading to pump failure or leakage of hazardous media. Therefore, sacrificing structural strength solely for magnetic field penetration is undesirable.

2. Structural Strength: A Physical Guarantee for Safe Operation

When designing the isolation sleeve as a pressure-bearing boundary, factors such as maximum operating pressure, thermal stresses caused by temperature fluctuations, material fatigue life, and media corrosiveness must be considered. Increasing wall thickness is the most direct way to improve strength, but it significantly increases magnetic resistance in the magnetic circuit, resulting in reduced magnetic force transmission efficiency, increased motor load, and even "decoupling"—where the outer magnetic rotor rotates while the inner magnetic rotor cannot follow, causing the pump to stop operating. Furthermore, eddy current losses are a side effect of thick-walled metal isolation sleeves. Alternating magnetic fields induce eddy currents in conductive materials, generating heat. This not only reduces efficiency but can also cause the isolating sleeve to heat up sharply, affecting magnet performance and even inducing creep or oxidation. Therefore, improving structural strength must be done without significantly degrading magnetic properties.

3. Material Selection and Structural Optimization: A Key Path to a Balance

The key to resolving this conflict lies in collaborative innovation in materials science and structural design. First, alloys with low magnetic permeability, high mechanical strength, and excellent corrosion resistance are preferred. Second, multi-physics coupled finite element analysis (FEM) simulations accurately calculate the stress distribution and deformation of the isolating sleeve under the combined effects of pressure, temperature, and magnetic fields, thereby optimizing the wall thickness distribution. For example, a constant-strength, variable-section structure can be designed, with appropriate thickness increase in stress concentration areas and thinner thickness in magnetic field coupling areas, achieving a balance between strength and magnetic properties. Furthermore, advanced manufacturing processes such as cold rolling and vacuum electron beam welding ensure uniform isolating sleeve wall thickness and dense welds, reducing defect sources and improving overall reliability. Surface treatment techniques such as shot peening can also introduce residual compressive stresses, improving fatigue life.

In summary, balancing magnetic field penetration and structural strength in a metal magnetic gear pump isn't a simple trade-off; it's a systematic engineering effort involving multiple disciplines, including materials, structures, electromagnetism, and thermal dynamics. Through scientific material selection, precise design, simulation verification, and advanced manufacturing, we can maximize magnetic circuit efficiency while ensuring safe pressure bearing.

1. Magnetic Field Penetration: The Core Requirement for Efficient Power Transmission

In a magnetic gear pump, power is transmitted through magnetic coupling between the outer and inner magnetic rotors. A metal isolation sleeve separates the two, completely sealing the pump chamber from the outside world. The magnetic field must penetrate this isolation sleeve to drive the inner magnetic rotor and the gears. Therefore, the magnetic permeability and thickness of the isolation sleeve material directly affect the efficiency of magnetic power transmission. Ideally, the isolation sleeve should be as thin as possible and made of low-permeability material to reduce magnetic resistance, enhance torque transmission, and minimize eddy current losses and temperature rise. However, an excessively thin isolation sleeve weakens its mechanical strength, making it unable to withstand the stresses of high-pressure operating conditions. Especially under high temperature, high pressure, or high speed conditions, the isolation sleeve may bulge, suffer fatigue cracks, or even rupture due to the internal and external pressure differential, leading to pump failure or leakage of hazardous media. Therefore, sacrificing structural strength solely for magnetic field penetration is undesirable.

2. Structural Strength: A Physical Guarantee for Safe Operation

When designing the isolation sleeve as a pressure-bearing boundary, factors such as maximum operating pressure, thermal stresses caused by temperature fluctuations, material fatigue life, and media corrosiveness must be considered. Increasing wall thickness is the most direct way to improve strength, but it significantly increases magnetic resistance in the magnetic circuit, resulting in reduced magnetic force transmission efficiency, increased motor load, and even "decoupling"—where the outer magnetic rotor rotates while the inner magnetic rotor cannot follow, causing the pump to stop operating. Furthermore, eddy current losses are a side effect of thick-walled metal isolation sleeves. Alternating magnetic fields induce eddy currents in conductive materials, generating heat. This not only reduces efficiency but can also cause the isolating sleeve to heat up sharply, affecting magnet performance and even inducing creep or oxidation. Therefore, improving structural strength must be done without significantly degrading magnetic properties.

3. Material Selection and Structural Optimization: A Key Path to a Balance

The key to resolving this conflict lies in collaborative innovation in materials science and structural design. First, alloys with low magnetic permeability, high mechanical strength, and excellent corrosion resistance are preferred. Second, multi-physics coupled finite element analysis (FEM) simulations accurately calculate the stress distribution and deformation of the isolating sleeve under the combined effects of pressure, temperature, and magnetic fields, thereby optimizing the wall thickness distribution. For example, a constant-strength, variable-section structure can be designed, with appropriate thickness increase in stress concentration areas and thinner thickness in magnetic field coupling areas, achieving a balance between strength and magnetic properties. Furthermore, advanced manufacturing processes such as cold rolling and vacuum electron beam welding ensure uniform isolating sleeve wall thickness and dense welds, reducing defect sources and improving overall reliability. Surface treatment techniques such as shot peening can also introduce residual compressive stresses, improving fatigue life.

In summary, balancing magnetic field penetration and structural strength in a metal magnetic gear pump isn't a simple trade-off; it's a systematic engineering effort involving multiple disciplines, including materials, structures, electromagnetism, and thermal dynamics. Through scientific material selection, precise design, simulation verification, and advanced manufacturing, we can maximize magnetic circuit efficiency while ensuring safe pressure bearing.