How to optimize the isolation sleeve of a metal magnetic gear pump to reduce eddy current losses?

Release Time : 2025-09-22

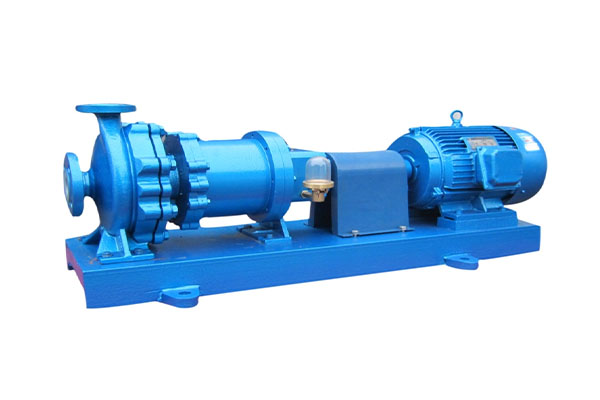

The isolation sleeve of a metal magnetic gear pump serves as a static seal between the inner and outer magnetic rotors. Optimizing its design is key to reducing eddy current losses and improving transmission efficiency. Eddy current losses arise from induced currents generated by electromagnetic induction within the isolation sleeve in an alternating magnetic field. These currents form a closed loop within the conductor and are converted into heat, resulting in energy loss. Eddy current losses are particularly prominent in metal isolation sleeves due to their high electrical conductivity. This phenomenon requires multi-dimensional optimization, including material selection, structural design, and process improvements.

Material selection is fundamental to reducing eddy current losses. Traditional metal isolation sleeves are often made of austenitic stainless steel, but this material has a low resistivity and high eddy current losses. In contrast, titanium alloys and Hastelloy alloys offer higher resistivity and mechanical strength, making them more attractive options. Titanium alloys have a resistivity more than twice that of stainless steel, while Hastelloy alloys have an even higher resistivity, significantly reducing the generation of induced currents. For non-high-pressure applications, non-metallic materials such as engineering plastics or ceramics can completely avoid eddy current losses, but this requires a trade-off between mechanical strength and pressure resistance. For example, although ceramic materials have near-zero eddy current losses, they are brittle and require high processing costs, limiting their widespread adoption in large-scale applications.

The wall thickness of the isolation sleeve must be designed to balance strength and eddy current losses. According to the principle of electromagnetic induction, eddy current losses are proportional to the square of the isolation sleeve wall thickness; therefore, thinner walls reduce losses. However, as a pressure-bearing component, the isolation sleeve must withstand the pressure of the medium within the pump. Excessively thin walls can cause deformation or rupture. Finite element analysis should be used to determine the minimum safe wall thickness during design, and the thickness should be minimized while meeting strength requirements. For example, using high-strength titanium alloys can reduce wall thickness by 30% while maintaining sufficient pressure-bearing capacity.

Structural optimization can further reduce eddy current losses. Eddy current density is highly concentrated on the surface of the isolation sleeve. Modifying the surface grain structure or employing a composite structure can effectively suppress eddy currents. For example, applying a high-resistivity material to the inner wall of the metal isolation sleeve or using surface hardening to increase the surface resistivity can reduce the eddy current path. Furthermore, the isolation sleeve's shape should avoid sharp edges or abrupt cross-sections to minimize eddy current accumulation. Streamlined designs can reduce local eddy currents caused by uneven magnetic field distribution, improving overall efficiency.

Matching magnetic field frequency to speed is an indirect means of optimizing eddy current losses. Eddy current losses are proportional to the square of the magnetic field frequency. Therefore, while meeting transmission requirements, appropriately reducing the magnetic field frequency can reduce losses. However, reducing speed may affect pump flow and head, necessitating a balance between efficiency and performance through system design. For example, variable frequency drive technology can dynamically adjust speed based on operating conditions, reducing frequency during low loads to reduce eddy current losses.

The design of the cooling and lubrication system is crucial for the long-term stable operation of the isolation sleeve. If heat generated by eddy currents is not dissipated promptly, the isolation sleeve will heat up, leading to demagnetization of the permanent magnets or degradation of material properties. The design must ensure sufficient coolant flow to dissipate the heat generated by the eddy currents. Typically, the coolant flow rate is 2%-3% of the pump's design flow rate, and flushing holes must be kept unobstructed to avoid clogging. For high-temperature media or high-power applications, an external cooling system can be used to enhance heat dissipation.

Improvements in manufacturing processes can improve the processing accuracy of the isolation sleeve and reduce eddy current losses. Precision casting or CNC machining ensures uniform wall thickness in the isolation sleeve, preventing eddy current concentration caused by excessive thickness in certain areas. Furthermore, surface treatment techniques such as polishing or coating can reduce the surface roughness of the isolation sleeve, thereby reducing frictional resistance during fluid flow and indirectly reducing hydraulic losses.

Optimizing the isolation sleeve of a metal magnetic gear pump requires a coordinated approach encompassing materials, structure, process, and system design. By selecting high-resistivity materials, reducing wall thickness, optimizing the structure, matching the magnetic field frequency, improving the cooling system, and enhancing manufacturing precision, eddy current losses can be significantly reduced, thereby improving the overall efficiency and reliability of the pump.