How do metal magnetic gear pumps perform when conveying high-viscosity or particulate-containing media?

Release Time : 2025-12-01

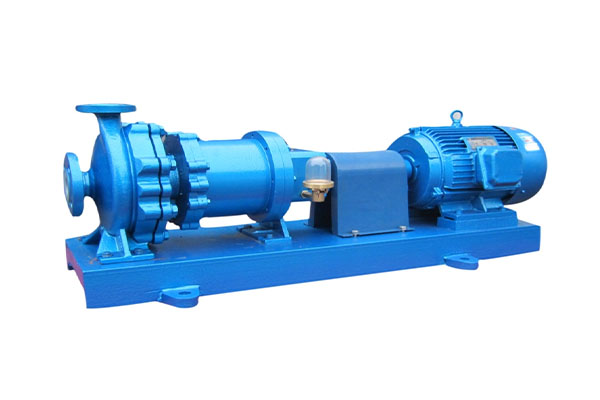

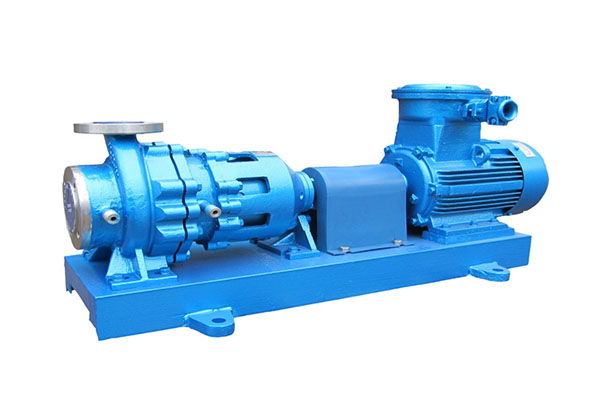

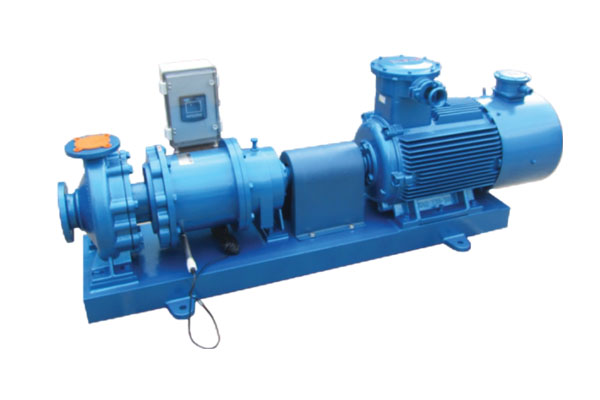

In industries such as chemical, petroleum, pharmaceutical, coating, resin, and lubrication systems, fluid transportation often faces complex conditions involving high viscosity, particulate matter, and even abrasive properties. Traditional centrifugal pumps are often inefficient or even fail to function properly in such scenarios. Metal magnetic gear pumps, with their unique structural design, fully enclosed drive system, and robust metal construction, are ideal for addressing these challenges. Their performance advantages are particularly prominent when conveying high-viscosity liquids or media containing small solid particles.

1. High-viscosity media transportation: Stable, efficient, and controllable flow rate

Metal magnetic gear pumps are positive displacement pumps. Their working principle relies on a pair of precisely meshing gears rotating to form a closed chamber, pushing the medium from the suction end to the discharge end. This mechanism is naturally suited for high-viscosity fluids—the higher the viscosity, the less leakage between the gears, and the higher the volumetric efficiency. Typically, metal magnetic gear pumps can efficiently transport media with viscosities ranging from tens to tens of thousands of centipoises, such as heavy oil, asphalt, epoxy resin, silicone oil, and adhesives. Compared to centrifugal pumps, which suffer from a sharp drop in head and a surge in energy consumption under high-viscosity conditions, gear pumps maintain stable flow output and high mechanical efficiency. Furthermore, their flow rate is linearly related to rotational speed, allowing for precise metering and process control through frequency conversion speed regulation, meeting the stringent requirements of fine chemicals for precise proportioning.

2. Adaptability to Particulate Media: Robust Structure and High Wear Resistance

When the medium contains micron-sized solid particles, the pump's wear resistance and clearance control capabilities are crucial. Metal magnetic gear pumps utilize high-strength alloy steel, stainless steel, or special hardened materials for their gears and pump bodies, with precision grinding and hardening treatments significantly enhancing wear resistance. Although the gear meshing clearance is small, the high rigidity of the metal material and its well-matched thermal expansion coefficients ensure stable operation even under particulate conditions, preventing jamming. In addition, some high-end models are equipped with replaceable wear-resistant bushings or employ a non-contact magnetic coupling design to further reduce the impact of particles on transmission components and extend service life.

3. Leak-Free Safety Advantage: Ensuring Reliable Transportation of High-Risk and Complex Media

High-viscosity or particulate-containing media often carry risks of flammability, toxicity, high cost, or environmental pollution. The metal magnetic gear pump utilizes magnetic drive technology, completely eliminating the need for mechanical seals or stuffing boxes required by traditional pumps, achieving fully enclosed, zero-leakage operation. The inner and outer magnetic rotors are separated by an isolation sleeve, completely sealing the media within the pump chamber. Even with long-term transportation of particulate-containing media, leakage will not occur due to seal wear. This feature not only significantly improves operational safety but also avoids the loss of expensive materials and environmental accidents, making it particularly suitable for transporting high-value or highly sensitive materials such as semiconductor chemicals, lithium battery slurries, and pharmaceutical intermediates.

4. Stable Operation and Convenient Maintenance: Reducing Total Life Cycle Costs

Thanks to the inherent low-pulsation characteristics of gear pumps and the high rigidity of the metal structure, the metal magnetic gear pump exhibits low vibration and noise when transporting high-viscosity or solid-containing media, minimizing impact on the pipeline system. Furthermore, its simple structure, without complex impellers or sealing components, requires only periodic bearing checks and lubrication replacements for routine maintenance, significantly reducing downtime and maintenance costs. Even under harsh operating conditions requiring continuous 24-hour operation, it maintains long-term reliable service.

In summary, the metal magnetic gear pump, with its positive displacement working principle, all-metal wear-resistant structure, zero-leakage magnetic drive, and excellent process adaptability, demonstrates superior comprehensive performance in the transportation of high-viscosity and particulate-containing media. It not only solves the pain points of traditional pumps in complex fluid conditions, such as low efficiency, easy wear, and easy leakage, but also, with its high reliability and safety, has become an indispensable key piece of equipment in modern process industries. With the continuous advancement of materials science and magnetic drive technology, its application boundaries will continue to expand, providing efficient, clean, and intelligent fluid solutions for more extreme operating conditions.

1. High-viscosity media transportation: Stable, efficient, and controllable flow rate

Metal magnetic gear pumps are positive displacement pumps. Their working principle relies on a pair of precisely meshing gears rotating to form a closed chamber, pushing the medium from the suction end to the discharge end. This mechanism is naturally suited for high-viscosity fluids—the higher the viscosity, the less leakage between the gears, and the higher the volumetric efficiency. Typically, metal magnetic gear pumps can efficiently transport media with viscosities ranging from tens to tens of thousands of centipoises, such as heavy oil, asphalt, epoxy resin, silicone oil, and adhesives. Compared to centrifugal pumps, which suffer from a sharp drop in head and a surge in energy consumption under high-viscosity conditions, gear pumps maintain stable flow output and high mechanical efficiency. Furthermore, their flow rate is linearly related to rotational speed, allowing for precise metering and process control through frequency conversion speed regulation, meeting the stringent requirements of fine chemicals for precise proportioning.

2. Adaptability to Particulate Media: Robust Structure and High Wear Resistance

When the medium contains micron-sized solid particles, the pump's wear resistance and clearance control capabilities are crucial. Metal magnetic gear pumps utilize high-strength alloy steel, stainless steel, or special hardened materials for their gears and pump bodies, with precision grinding and hardening treatments significantly enhancing wear resistance. Although the gear meshing clearance is small, the high rigidity of the metal material and its well-matched thermal expansion coefficients ensure stable operation even under particulate conditions, preventing jamming. In addition, some high-end models are equipped with replaceable wear-resistant bushings or employ a non-contact magnetic coupling design to further reduce the impact of particles on transmission components and extend service life.

3. Leak-Free Safety Advantage: Ensuring Reliable Transportation of High-Risk and Complex Media

High-viscosity or particulate-containing media often carry risks of flammability, toxicity, high cost, or environmental pollution. The metal magnetic gear pump utilizes magnetic drive technology, completely eliminating the need for mechanical seals or stuffing boxes required by traditional pumps, achieving fully enclosed, zero-leakage operation. The inner and outer magnetic rotors are separated by an isolation sleeve, completely sealing the media within the pump chamber. Even with long-term transportation of particulate-containing media, leakage will not occur due to seal wear. This feature not only significantly improves operational safety but also avoids the loss of expensive materials and environmental accidents, making it particularly suitable for transporting high-value or highly sensitive materials such as semiconductor chemicals, lithium battery slurries, and pharmaceutical intermediates.

4. Stable Operation and Convenient Maintenance: Reducing Total Life Cycle Costs

Thanks to the inherent low-pulsation characteristics of gear pumps and the high rigidity of the metal structure, the metal magnetic gear pump exhibits low vibration and noise when transporting high-viscosity or solid-containing media, minimizing impact on the pipeline system. Furthermore, its simple structure, without complex impellers or sealing components, requires only periodic bearing checks and lubrication replacements for routine maintenance, significantly reducing downtime and maintenance costs. Even under harsh operating conditions requiring continuous 24-hour operation, it maintains long-term reliable service.

In summary, the metal magnetic gear pump, with its positive displacement working principle, all-metal wear-resistant structure, zero-leakage magnetic drive, and excellent process adaptability, demonstrates superior comprehensive performance in the transportation of high-viscosity and particulate-containing media. It not only solves the pain points of traditional pumps in complex fluid conditions, such as low efficiency, easy wear, and easy leakage, but also, with its high reliability and safety, has become an indispensable key piece of equipment in modern process industries. With the continuous advancement of materials science and magnetic drive technology, its application boundaries will continue to expand, providing efficient, clean, and intelligent fluid solutions for more extreme operating conditions.