How does the IMC plastic double leakage protection magnetic centrifugal pump achieve true "zero leakage"?

Release Time : 2025-12-15

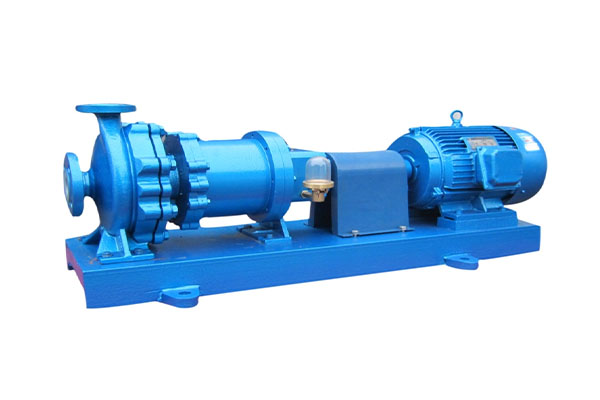

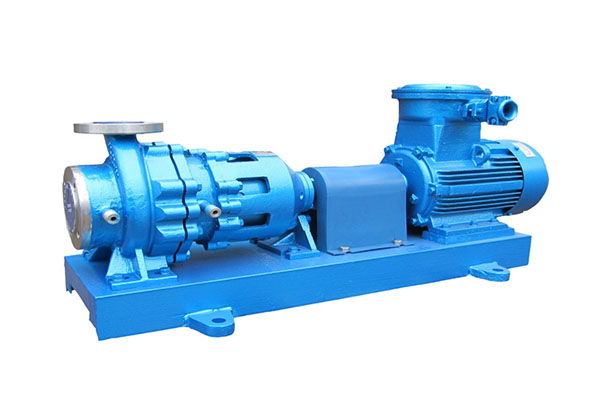

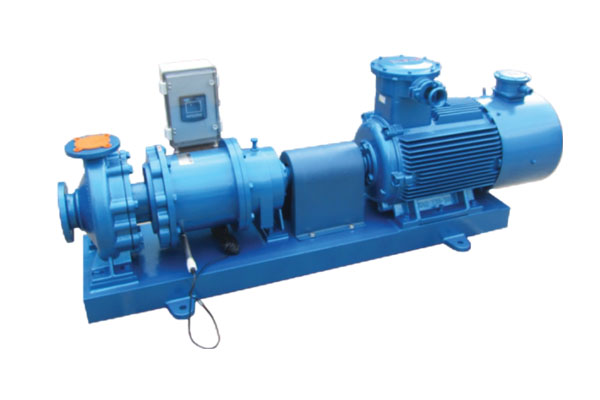

In industrial settings involving highly corrosive, toxic, or high-purity media, such as chemical processing, electroplating, etching, and wastewater treatment, the reliability of pump seals directly impacts production safety, environmental protection, and product quality. Traditional mechanical seal pumps, due to the presence of dynamic sealing points, are prone to wear and leakage over long-term operation. The IMC plastic double leakage protection magnetic centrifugal pump, with its unique "shaft-seal-free, fully enclosed" design combined with multiple leak-proof structures, truly achieves zero-leakage operation. Its "dual leakage protection" mechanism, in particular, elevates safety redundancy to a new level.

1. Magnetic Drive: Eliminating Dynamic Seals at the Source

The core of the IMC plastic magnetic pump lies in its magnetic coupling transmission technology. The motor drives the outer magnetic rotor to rotate, and the magnetic field penetrates the isolation sleeve, driving the inner magnetic rotor and impeller to rotate synchronously. The entire transmission process eliminates the need for a mechanical shaft to pass through the pump casing, completely eliminating the mechanical seals or packing seals required in traditional pumps—these are the main sources of leakage. Because the pump chamber is completely sealed, the medium is entirely confined within the pump body, ensuring the safety of operators and the environment even when conveying highly hazardous media such as hydrofluoric acid, concentrated sulfuric acid, and chlor-alkali solutions.

2. Double Leak-Proof Structure: Double Insurance for Safety

The "double leak-proof" design of the IMC pump is not just a marketing term, but rather reflected in the redundant design of key components:

First layer of protection: The pump body and impeller are made of carbon fiber filament-reinforced fluoroplastic, possessing excellent corrosion resistance and mechanical strength; the internal flow channel is fully lined with fluoroplastic, and the inner wall of the joint is a steel plate lined with fluoroplastic, ensuring pressure resistance while preventing metal-to-metal contact with corrosive media.

Second layer of protection: A high-performance PEEK isolation sleeve is installed between the inner and outer magnetic rotors. PEEK material is not only resistant to high temperatures and chemical corrosion, but also has low magnetic resistance, ensuring efficient magnetic force transmission. Even in extreme cases where a minor leak occurs in the inner rotor assembly, the isolation sleeve can still completely seal the medium within the internal cavity, preventing leakage.

Furthermore, the double-layer cover plate and double-support structure further enhance the pump body rigidity, reduce vibration and deformation, and prevent seal failure due to structural fatigue.

3. High-performance material combination: Balancing corrosion resistance, strength, and reliability

To cope with harsh operating conditions, the IMC pump uses silicon carbide sliding bearings on key friction pairs. Silicon carbide has high hardness, good self-lubricating properties, and strong corrosion resistance, enabling stable operation even in unlubricated or particulate media, significantly extending the pump's service life. Meanwhile, the carbon steel pump casing provides structural strength support externally, while the internal perfluoroplastic lining isolates corrosion, forming a composite advantage of "outer steel, inner plastic." This ensures pressure resistance while resisting the erosion of various strong acids, strong alkalis, and organic solvents.

4. Application Scenario Verification: Zero Leakage is Not a Theory, But a Practice

In semiconductor cleaning lines, IMC pumps are used to deliver high-purity etching solutions, ensuring a cleanroom environment with zero leakage. In electroplating workshops, they continuously deliver solutions containing cyanide or chromic acid, preventing the escape of toxic gases. In environmental engineering, when treating wastewater containing heavy metals, the double leak-proof design effectively prevents secondary pollution. These practical applications fully demonstrate that its "zero leakage" capability can withstand industrial-grade testing.

IMC plastic double leakage protection magnetic centrifugal pump employs magnetic drive to eliminate dynamic seals, a PEEK isolation sleeve and fluoroplastic lining to create a double barrier, and silicon carbide bearings to ensure long-term operation. From its principle to its structure, it is meticulously designed to achieve the safety goal of "no media leakage and zero environmental risk." In today's world, where green manufacturing and inherent safety requirements are increasingly stringent, this approach of sacrificing design redundancy for absolute reliability is precisely the right direction for the development of high-end process pumps.

1. Magnetic Drive: Eliminating Dynamic Seals at the Source

The core of the IMC plastic magnetic pump lies in its magnetic coupling transmission technology. The motor drives the outer magnetic rotor to rotate, and the magnetic field penetrates the isolation sleeve, driving the inner magnetic rotor and impeller to rotate synchronously. The entire transmission process eliminates the need for a mechanical shaft to pass through the pump casing, completely eliminating the mechanical seals or packing seals required in traditional pumps—these are the main sources of leakage. Because the pump chamber is completely sealed, the medium is entirely confined within the pump body, ensuring the safety of operators and the environment even when conveying highly hazardous media such as hydrofluoric acid, concentrated sulfuric acid, and chlor-alkali solutions.

2. Double Leak-Proof Structure: Double Insurance for Safety

The "double leak-proof" design of the IMC pump is not just a marketing term, but rather reflected in the redundant design of key components:

First layer of protection: The pump body and impeller are made of carbon fiber filament-reinforced fluoroplastic, possessing excellent corrosion resistance and mechanical strength; the internal flow channel is fully lined with fluoroplastic, and the inner wall of the joint is a steel plate lined with fluoroplastic, ensuring pressure resistance while preventing metal-to-metal contact with corrosive media.

Second layer of protection: A high-performance PEEK isolation sleeve is installed between the inner and outer magnetic rotors. PEEK material is not only resistant to high temperatures and chemical corrosion, but also has low magnetic resistance, ensuring efficient magnetic force transmission. Even in extreme cases where a minor leak occurs in the inner rotor assembly, the isolation sleeve can still completely seal the medium within the internal cavity, preventing leakage.

Furthermore, the double-layer cover plate and double-support structure further enhance the pump body rigidity, reduce vibration and deformation, and prevent seal failure due to structural fatigue.

3. High-performance material combination: Balancing corrosion resistance, strength, and reliability

To cope with harsh operating conditions, the IMC pump uses silicon carbide sliding bearings on key friction pairs. Silicon carbide has high hardness, good self-lubricating properties, and strong corrosion resistance, enabling stable operation even in unlubricated or particulate media, significantly extending the pump's service life. Meanwhile, the carbon steel pump casing provides structural strength support externally, while the internal perfluoroplastic lining isolates corrosion, forming a composite advantage of "outer steel, inner plastic." This ensures pressure resistance while resisting the erosion of various strong acids, strong alkalis, and organic solvents.

4. Application Scenario Verification: Zero Leakage is Not a Theory, But a Practice

In semiconductor cleaning lines, IMC pumps are used to deliver high-purity etching solutions, ensuring a cleanroom environment with zero leakage. In electroplating workshops, they continuously deliver solutions containing cyanide or chromic acid, preventing the escape of toxic gases. In environmental engineering, when treating wastewater containing heavy metals, the double leak-proof design effectively prevents secondary pollution. These practical applications fully demonstrate that its "zero leakage" capability can withstand industrial-grade testing.

IMC plastic double leakage protection magnetic centrifugal pump employs magnetic drive to eliminate dynamic seals, a PEEK isolation sleeve and fluoroplastic lining to create a double barrier, and silicon carbide bearings to ensure long-term operation. From its principle to its structure, it is meticulously designed to achieve the safety goal of "no media leakage and zero environmental risk." In today's world, where green manufacturing and inherent safety requirements are increasingly stringent, this approach of sacrificing design redundancy for absolute reliability is precisely the right direction for the development of high-end process pumps.