How does the IMC plastic double leakage protection magnetic centrifugal pump achieve zero leakage under double-layer protection?

Release Time : 2025-12-29

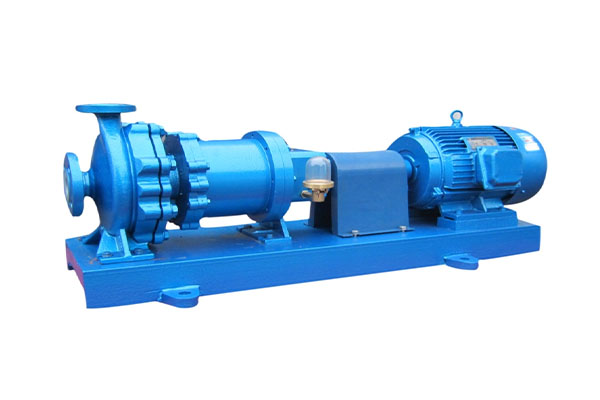

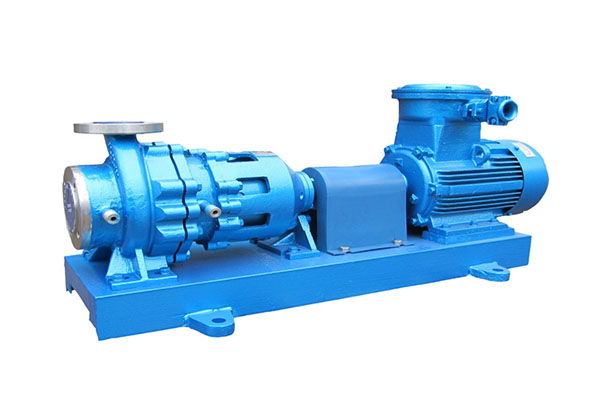

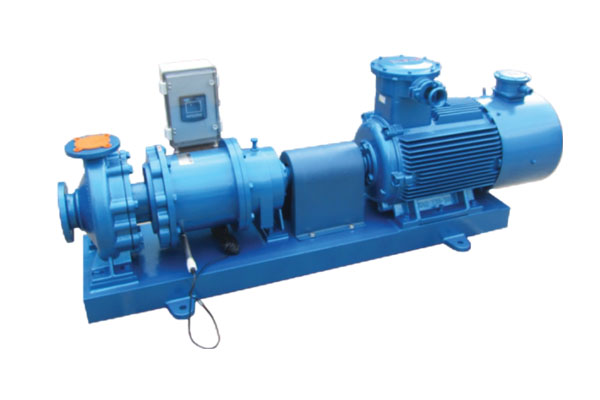

In high-risk fluid transportation fields such as chemical, pharmaceutical, electroplating, environmental protection, and new energy industries, the sealing reliability of pumps directly affects production safety, environmental protection, and operating costs. Traditional mechanical seal pumps face long-term leakage risks due to dynamic sealing points. The IMC plastic double leakage protection magnetic centrifugal pump, with its fully enclosed shaftless design and five core protection technologies, achieves true "zero leakage," becoming a safety benchmark for fluid transportation under harsh operating conditions. Its superior performance stems from systematic innovation in structure, materials, and protection mechanisms.

1. Double-layer cover and double support: Stable structure and reliable operation

The IMC pump adopts a double-layer cover design. The outer layer is a high-strength carbon steel pressure-bearing shell, and the inner layer is a corrosion-resistant fluoroplastic lining, forming a composite structure that combines rigidity and flexibility. Combined with a double support structure, where high-precision bearing support points are provided at both ends of the pump shaft, it effectively suppresses radial runout and vibration of the rotor during high-speed operation. This design not only enhances the overall rigidity of the pump but also significantly extends the life of the sliding bearings, ensuring stable operation even when conveying media containing microparticles or under frequent start-stop conditions, thus preventing seal failure due to structural deformation.

2. Carbon Steel Shell + Fluoroplastic Liner: Balancing Strength and Corrosion Resistance

The pump casing is made of high-quality cast carbon steel, providing strong mechanical strength and pressure resistance, capable of withstanding working pressures up to 1.6 MPa. All flow path surfaces in contact with the media—including the inner walls of the inlet and outlet joints—are lined with fluoroplastic steel plates, forming a continuous and dense corrosion barrier. This structure overcomes the shortcomings of all-plastic pumps in terms of strength while avoiding the rapid deterioration of metal pumps in corrosive media such as strong acids, strong alkalis, and organic solvents. It is suitable for a wide range of media, including highly hazardous chemicals such as sulfuric acid, hydrochloric acid, hydrofluoric acid, and sodium hypochlorite.

3. High-Performance Composite Materials: Ultimate Optimization of Key Components

IMC pumps extensively utilize advanced engineering materials in their core functional components. The isolation sleeve is made of PEEK material, possessing excellent mechanical strength, high-temperature resistance, and low magnetic eddy current loss, effectively improving magnetic transmission efficiency and reducing temperature rise. The impeller and pump body lining use carbon fiber filament-reinforced fluoroplastic, maintaining the excellent corrosion resistance of fluoroplastic while significantly improving creep resistance and wear resistance, suitable for slightly abrasive conditions with a solids content ≤5%.

4. Silicon Carbide Sliding Bearings: Long Life, Low Friction, Self-Lubricating

Traditional magnetic pumps often suffer from rotor eccentricity or even shaft seizure due to bearing wear. The IMC pump uses high-purity reaction-sintered silicon carbide sliding bearings with a hardness exceeding HV2800, extremely low friction coefficient, and excellent self-lubricating properties. Even under brief periods of fluid interruption or dry operation, its high thermal conductivity allows for rapid heat dissipation, preventing thermal cracking. Combined with a precise axial thrust design, it effectively balances hydraulic axial forces, ensuring tens of thousands of hours of trouble-free operation.

5. Dual Leakage Protection Device: Redundant Safety for Complete Safety

The most core innovation lies in its dual leakage protection device. The first layer is the seal-free structure of the magnetic drive itself, completely eliminating dynamic seal leakage points. The second layer consists of a leakage monitoring chamber and pressure/level sensors installed on the outside of the isolation sleeve. In the event of even a trace leakage of the medium due to extreme circumstances, the system can immediately issue an alarm and interlock to shut down, preventing hazardous media from leaking into the environment.

The IMC plastic double leakage protection magnetic centrifugal pump is not simply a combination of magnetic drive and plastic material; rather, it achieves a complete zero-leakage guarantee system through a deep integration of structural reinforcement, material upgrades, and multiple protections. In today's increasingly important context of safe production and green manufacturing, it is not only an ideal choice for conveying corrosive, toxic, flammable, and explosive media, but also a key piece of equipment for enterprises to practice responsible care and improve inherent safety levels. Dual protection not only ensures the pump's reliability but also represents a solemn commitment to life and the environment.

1. Double-layer cover and double support: Stable structure and reliable operation

The IMC pump adopts a double-layer cover design. The outer layer is a high-strength carbon steel pressure-bearing shell, and the inner layer is a corrosion-resistant fluoroplastic lining, forming a composite structure that combines rigidity and flexibility. Combined with a double support structure, where high-precision bearing support points are provided at both ends of the pump shaft, it effectively suppresses radial runout and vibration of the rotor during high-speed operation. This design not only enhances the overall rigidity of the pump but also significantly extends the life of the sliding bearings, ensuring stable operation even when conveying media containing microparticles or under frequent start-stop conditions, thus preventing seal failure due to structural deformation.

2. Carbon Steel Shell + Fluoroplastic Liner: Balancing Strength and Corrosion Resistance

The pump casing is made of high-quality cast carbon steel, providing strong mechanical strength and pressure resistance, capable of withstanding working pressures up to 1.6 MPa. All flow path surfaces in contact with the media—including the inner walls of the inlet and outlet joints—are lined with fluoroplastic steel plates, forming a continuous and dense corrosion barrier. This structure overcomes the shortcomings of all-plastic pumps in terms of strength while avoiding the rapid deterioration of metal pumps in corrosive media such as strong acids, strong alkalis, and organic solvents. It is suitable for a wide range of media, including highly hazardous chemicals such as sulfuric acid, hydrochloric acid, hydrofluoric acid, and sodium hypochlorite.

3. High-Performance Composite Materials: Ultimate Optimization of Key Components

IMC pumps extensively utilize advanced engineering materials in their core functional components. The isolation sleeve is made of PEEK material, possessing excellent mechanical strength, high-temperature resistance, and low magnetic eddy current loss, effectively improving magnetic transmission efficiency and reducing temperature rise. The impeller and pump body lining use carbon fiber filament-reinforced fluoroplastic, maintaining the excellent corrosion resistance of fluoroplastic while significantly improving creep resistance and wear resistance, suitable for slightly abrasive conditions with a solids content ≤5%.

4. Silicon Carbide Sliding Bearings: Long Life, Low Friction, Self-Lubricating

Traditional magnetic pumps often suffer from rotor eccentricity or even shaft seizure due to bearing wear. The IMC pump uses high-purity reaction-sintered silicon carbide sliding bearings with a hardness exceeding HV2800, extremely low friction coefficient, and excellent self-lubricating properties. Even under brief periods of fluid interruption or dry operation, its high thermal conductivity allows for rapid heat dissipation, preventing thermal cracking. Combined with a precise axial thrust design, it effectively balances hydraulic axial forces, ensuring tens of thousands of hours of trouble-free operation.

5. Dual Leakage Protection Device: Redundant Safety for Complete Safety

The most core innovation lies in its dual leakage protection device. The first layer is the seal-free structure of the magnetic drive itself, completely eliminating dynamic seal leakage points. The second layer consists of a leakage monitoring chamber and pressure/level sensors installed on the outside of the isolation sleeve. In the event of even a trace leakage of the medium due to extreme circumstances, the system can immediately issue an alarm and interlock to shut down, preventing hazardous media from leaking into the environment.

The IMC plastic double leakage protection magnetic centrifugal pump is not simply a combination of magnetic drive and plastic material; rather, it achieves a complete zero-leakage guarantee system through a deep integration of structural reinforcement, material upgrades, and multiple protections. In today's increasingly important context of safe production and green manufacturing, it is not only an ideal choice for conveying corrosive, toxic, flammable, and explosive media, but also a key piece of equipment for enterprises to practice responsible care and improve inherent safety levels. Dual protection not only ensures the pump's reliability but also represents a solemn commitment to life and the environment.