How does the IMC metal double leakage protection magnetic centrifugal pump withstand the triple challenges of high pressure, high temperature, and vibration?

Release Time : 2026-01-12

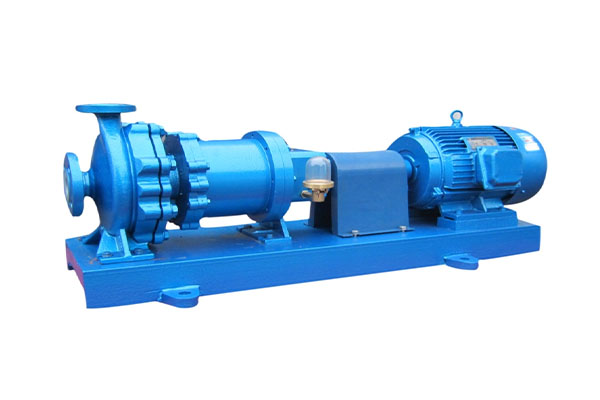

In high-end manufacturing fields such as chemical, pharmaceutical, semiconductor, and new energy industries, the transportation of highly corrosive, high-purity, or flammable and explosive media places extremely stringent demands on pump equipment: it must withstand high system pressure and high process temperatures, resist mechanical vibration and chemical corrosion during long-term operation, and ensure "zero leakage"—any minor seal failure could lead to safety accidents or product contamination. The IMC metal double leakage protection magnetic centrifugal pump, with its fully enclosed shaftless design and five core technologies, successfully builds an impenetrable defense, maintaining stable, safe, and efficient operation even under the triple pressure of high pressure, high temperature, and vibration.

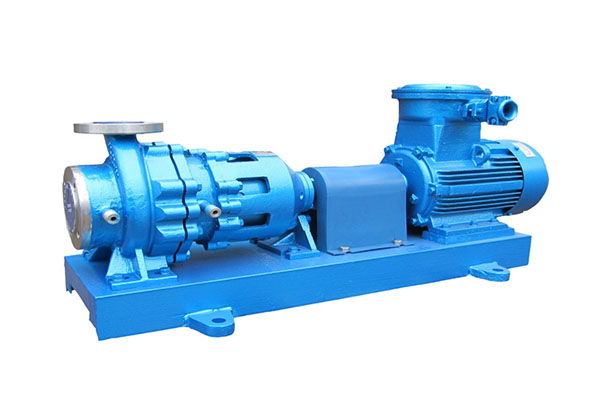

1. Double-layer cover plate + double support: Constructing a rigid structural fortress

Faced with system pressure fluctuations or water hammer impacts, the IMC pump adopts a double-layer cover plate design, with an outer pressure-bearing layer and an inner sealing layer, forming redundant protection; at the same time, a double mechanical support structure is set between the pump body and the motor bracket, significantly enhancing the overall rigidity of the machine. This design effectively suppresses the risk of casing deformation and resonance under high-speed rotation. Even under operating pressures above 10 bar or frequent start-stop conditions, it maintains rotor concentricity, avoiding wear or leakage caused by eccentricity and providing robust structural support for high-pressure environments.

2. Precision Flow Channel Treatment: Improved Efficiency, Reduced Heat Load

The impeller is the core of energy conversion. IMC pumps perform high-precision grinding and mirror polishing on the impeller flow channels, significantly reducing fluid friction resistance and turbulence losses. This not only improves hydraulic efficiency but, more importantly, reduces localized temperature rise caused by energy loss. When conveying high-temperature media, the smooth flow channels prevent hot spot accumulation, prevent material thermal aging, and mitigate performance degradation caused by high temperatures from the source.

3. Dual-Material Isolation Sleeve: Perfect Balance of Corrosion Resistance and Strength

The core of the magnetic pump lies in the isolation sleeve—it completely isolates the inner magnetic rotor from the outer magnetic drive, achieving contactless transmission. IMC pumps offer two cutting-edge solutions:

- Stretched-welded Hastelloy alloy isolation sleeve: Provides excellent resistance to strong acids, alkalis, and chloride ion corrosion, suitable for extreme chemical environments;

- Carbon fiber reinforced PEEK composite isolation sleeve: Combines high strength, low eddy current loss, and excellent temperature resistance, while its non-metallic properties completely eliminate eddy current heating.

Both sleeves are manufactured using precision welding or integral molding processes, ensuring no bulging or cracking under high temperature and pressure, forming the first line of defense against media corrosion.

4. Tungsten carbide sliding bearings: Ultra-hard, wear-resistant, high-temperature self-lubricating

Traditional bearings are prone to wear in dry operation or high-solids media. IMC pumps use integrally sintered tungsten carbide sliding bearings with a hardness exceeding HRA90, offering 10 times the wear resistance of stainless steel. Their microporous structure allows for liquid film lubrication during operation, preventing bearing seizure even during short-term liquid interruption. More importantly, tungsten carbide maintains dimensional stability even at 300℃, and combined with an optimized axial thrust structure, effectively absorbs rotor axial forces, significantly reducing vibration transmission and ensuring long-term stable operation.

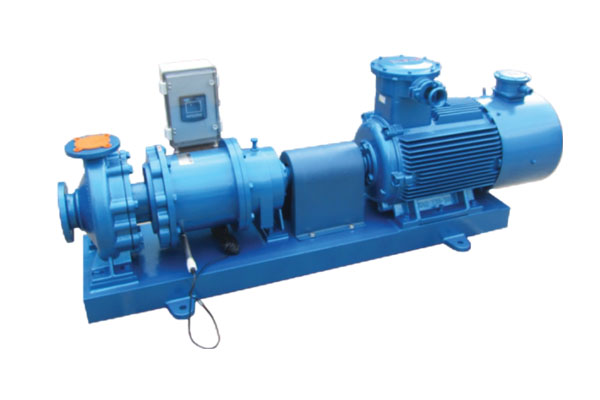

5. Dual Leakage Protection Device: The Last Line of Defense for Intrinsic Safety

Even in extreme failure conditions, the IMC pump features dual leakage protection: the first layer is the integrity seal of the isolation sleeve itself; the second layer is a leakage detection chamber and drainage channel integrated at the bottom of the pump body. If even a small amount of leakage occurs in the internal magnetic cavity, the medium will be directed to the safe collection port instead of leaking outwards, and an alarm can be triggered. This "double insurance" mechanism...

The IMC metal double leakage protection magnetic centrifugal pump is not merely a collection of single technologies, but a systematic innovation that deeply integrates structural mechanics, materials science, and fluid engineering. With its double-layered protective body, precision flow channel, special material framework, ultra-hard bearing reinforcement, and intelligent leak-proof design, it confidently withstands the extreme tests of high pressure, high temperature, and vibration, providing a reliable "zero leakage" commitment for high-risk industrial processes—allowing hazardous media to flow quietly under absolute control.

1. Double-layer cover plate + double support: Constructing a rigid structural fortress

Faced with system pressure fluctuations or water hammer impacts, the IMC pump adopts a double-layer cover plate design, with an outer pressure-bearing layer and an inner sealing layer, forming redundant protection; at the same time, a double mechanical support structure is set between the pump body and the motor bracket, significantly enhancing the overall rigidity of the machine. This design effectively suppresses the risk of casing deformation and resonance under high-speed rotation. Even under operating pressures above 10 bar or frequent start-stop conditions, it maintains rotor concentricity, avoiding wear or leakage caused by eccentricity and providing robust structural support for high-pressure environments.

2. Precision Flow Channel Treatment: Improved Efficiency, Reduced Heat Load

The impeller is the core of energy conversion. IMC pumps perform high-precision grinding and mirror polishing on the impeller flow channels, significantly reducing fluid friction resistance and turbulence losses. This not only improves hydraulic efficiency but, more importantly, reduces localized temperature rise caused by energy loss. When conveying high-temperature media, the smooth flow channels prevent hot spot accumulation, prevent material thermal aging, and mitigate performance degradation caused by high temperatures from the source.

3. Dual-Material Isolation Sleeve: Perfect Balance of Corrosion Resistance and Strength

The core of the magnetic pump lies in the isolation sleeve—it completely isolates the inner magnetic rotor from the outer magnetic drive, achieving contactless transmission. IMC pumps offer two cutting-edge solutions:

- Stretched-welded Hastelloy alloy isolation sleeve: Provides excellent resistance to strong acids, alkalis, and chloride ion corrosion, suitable for extreme chemical environments;

- Carbon fiber reinforced PEEK composite isolation sleeve: Combines high strength, low eddy current loss, and excellent temperature resistance, while its non-metallic properties completely eliminate eddy current heating.

Both sleeves are manufactured using precision welding or integral molding processes, ensuring no bulging or cracking under high temperature and pressure, forming the first line of defense against media corrosion.

4. Tungsten carbide sliding bearings: Ultra-hard, wear-resistant, high-temperature self-lubricating

Traditional bearings are prone to wear in dry operation or high-solids media. IMC pumps use integrally sintered tungsten carbide sliding bearings with a hardness exceeding HRA90, offering 10 times the wear resistance of stainless steel. Their microporous structure allows for liquid film lubrication during operation, preventing bearing seizure even during short-term liquid interruption. More importantly, tungsten carbide maintains dimensional stability even at 300℃, and combined with an optimized axial thrust structure, effectively absorbs rotor axial forces, significantly reducing vibration transmission and ensuring long-term stable operation.

5. Dual Leakage Protection Device: The Last Line of Defense for Intrinsic Safety

Even in extreme failure conditions, the IMC pump features dual leakage protection: the first layer is the integrity seal of the isolation sleeve itself; the second layer is a leakage detection chamber and drainage channel integrated at the bottom of the pump body. If even a small amount of leakage occurs in the internal magnetic cavity, the medium will be directed to the safe collection port instead of leaking outwards, and an alarm can be triggered. This "double insurance" mechanism...

The IMC metal double leakage protection magnetic centrifugal pump is not merely a collection of single technologies, but a systematic innovation that deeply integrates structural mechanics, materials science, and fluid engineering. With its double-layered protective body, precision flow channel, special material framework, ultra-hard bearing reinforcement, and intelligent leak-proof design, it confidently withstands the extreme tests of high pressure, high temperature, and vibration, providing a reliable "zero leakage" commitment for high-risk industrial processes—allowing hazardous media to flow quietly under absolute control.